Weld Colors Explained – What They Indicate

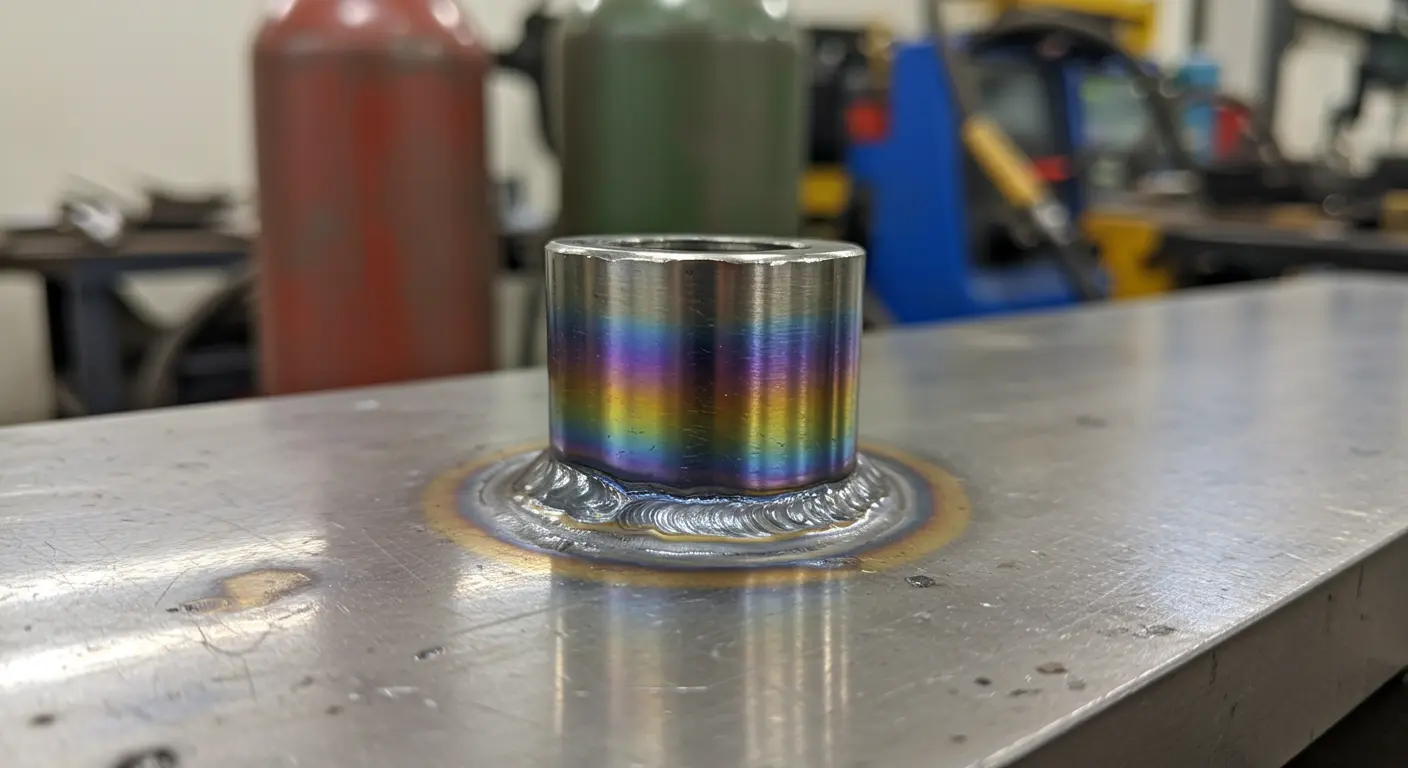

When examining a stainless steel weld, the rainbow of colors that often appears reveals important information about the welding process itself. These vibrant hues aren’t merely aesthetic features—they’re diagnostic indicators of oxidation levels, temperature exposure, and ultimately, weld quality.

Color formation in welds signals the development of an oxide layer on the metal surface. This occurs when superheated metal encounters atmospheric oxygen during welding. The resulting color directly reflects oxide layer thickness—darker shades reveal more extensive oxidation. This oxidation significantly affects stainless steel’s prized corrosion resistance.

The interpretation of weld colors depends on several factors:

-

The welding process used

-

The base material

-

Industry standards

-

The specific application

For materials like titanium, weld colors become particularly reliable quality markers. A bright silver finish indicates pristine welding conditions, while blue or purple hues signal contamination that may weaken structural integrity.

Color Progression in Welding – From Chrome to Black

Stainless steel welds exhibit a predictable color progression that mirrors escalating oxidation levels. Understanding this sequence is important for quality assessment and performance prediction in harsh environments.

This chromatic journey reveals escalating oxidation and its impact on corrosion resistance:

-

Chrome/Silver: Indicates little to no oxidation, representing the ideal condition for maximum corrosion resistance.

-

Straw (Light Gold): Signals light oxidation has occurred.

-

Red/Brown: Indicates moderate oxidation that may begin to compromise corrosion resistance.

-

Blue: Represents a considerable oxide layer that reduces corrosion resistance.

-

Purple/Black: Appears with extensive oxidation, indicating the thickest oxide layers and the greatest reduction in corrosion resistance.

Oxidation and Its Impact on Weld Colors

Oxidation—the reaction between hot metal surfaces and atmospheric oxygen—drives the fundamental process behind weld coloration. This reaction doesn’t merely change appearance; it can alter the weld’s crystalline structure, directly impacting mechanical properties and corrosion resistance.

Oxidation’s effects extend far beyond aesthetics, potentially weakening joints through porosity formation—microscopic voids that compromise structural integrity. Severe oxidation even manifests in the welding flame itself: watch for color loss in the flame cone or harsh, pointed cone formations during welding.

Here’s a fundamental principle: the closer your weld color matches the original base metal, the less oxidation has occurred. This similarity indicates superior preservation of corrosion-resistant properties.

Preventing excessive oxidation requires using shielding gases—argon, helium, or specialized flux coatings—that form protective barriers around molten weld pools. These measures keep oxygen away from the welding zone. The effectiveness of this shielding directly influences the resulting weld color and, by extension, the weld’s quality and performance characteristics.

Controlling Weld Colors – Techniques and Best Practices

Mastering weld color control requires technical skill, material knowledge, and precise execution. Whether you’re minimizing coloration for optimal corrosion resistance or deliberately crafting vibrant welds for aesthetic appeal, understanding the underlying factors is crucial.

When pursuing intentionally colorful welds, material selection is most important. Stainless steel and titanium respond beautifully to controlled oxidation, yielding spectacular colors under precise heart conditions. Surface preparation is also important: meticulous cleaning eliminates contaminants that might sabotage your color development goals.

Shielding gas composition and flow rates have significant impact over weld coloration. Strategic parameter adjustments enable precise control over oxidation levels. Consider this technique: slightly reducing gas coverage permits calculated oxygen exposure, developing desired colors while maintaining structural integrity.

Real-time color monitoring provides immediate information on oxidation progression. Seasoned welders develop a strong understanding of how heat input, travel speed, and cooling rates influence color development. Mastering these techniques demands both practice and precision—the boundary between stunning coloration and damaging oxidation remains razor-thin.

Heat Control – Key to Quality Welds

Heat control is the most important factor determining both weld quality and coloration. In TIG welding especially, mastering heat input through precise arc modulation directly shapes the metallurgical properties and visual appeal of your finished weld.

Heat input and weld color share a direct relationship: elevated temperatures intensify oxidation and darken colors, while controlled heat preserves lighter tones. Striking the perfect heat balance demands mastery of several interconnected variables:

-

Travel speed

-

Electrode angle

-

Arc length

Effective heat control starts with meticulous joint preparation. Pristine, well-fitted joints demand less heat for proper fusion, naturally reducing oxidation risks. Consistent travel speed prevents those troublesome hot spots that create uneven coloration and compromise weld integrity.

Pulse welding is an advanced heat control strategy, alternating between high and low current to allow strategic cooling between pulses. This sophisticated approach dramatically reduces overall heat input while preserving penetration quality. When working critical applications where corrosion resistance cannot be compromised, these refined strategies are necessary for achieving superior, minimally oxidized results.

Shielding Gas – Protecting Your Welds

Shielding gas functions as your primary defense against atmospheric contamination, directly affecting over both weld color and quality. This protective envelope of inert or semi-inert gas keeps oxygen from the weld zone, preventing or minimizing oxidation as molten metal transitions to solid form.

Your shielding gas selection significantly impacts both weld appearance and performance characteristics. Pure argon—the preferred choice for stainless steel TIG welding—delivers exceptional protection and typically yields minimal coloration under proper application. Specialized gas mixtures incorporating helium or hydrogen can modify heat transfer dynamics while further suppressing oxidation potential.

Primary torch shielding is not enough—backing gas protection is also important for comprehensive color control. This secondary protection shields the weld’s underside from atmospheric contamination, preventing root-side oxidation. Without proper backing gas, even visually perfect welds can harbor heavily oxidized root surfaces that silently compromise both corrosion resistance and mechanical integrity.

Proper gas coverage requires attention to several factors:

-

Flow Rate: Must be sufficient to displace air without creating turbulence that could draw in oxygen.

-

Gas Lens Systems: Improve gas distribution for more effective coverage.

-

Cup Size: Must be selected to adequately protect both the weld pool and the cooling metal.

Understanding Heat Tint Charts for Welds

Heat tint charts are valuable visual reference guides, creating clear correlations between weld colors, temperature exposure, and oxidation levels. These powerful tools enable welding professionals to rapidly assess weld quality, predict performance characteristics, and verify compliance with industry-specific standards.

These charts provide instant visual feedback on weld quality without demanding expensive testing equipment. A simple color comparison reveals whether oxidation levels meet application-specific requirements.

Industry-specific color tolerances make these charts important for quality control. Welds displaying excessive oxidation colors often require intervention—mechanical cleaning, chemical treatment, or both—to restore peak corrosion resistance.

Using Heat Tint Charts – A Practical Guide

Successfully implementing heat tint charts in your welding practice requires mastering both color interpretation techniques and their practical application. Begin by establishing proper lighting conditions—natural daylight or color-balanced artificial lighting ensures the most accurate color assessment possible.

During weld evaluation, systematically compare observed colors against your reference chart, carefully noting their position on the oxidation spectrum. Keep in mind that specific alloys can subtly alter color appearance—material familiarity becomes your ally here.

Critical applications demand photographic documentation under standardized lighting conditions. This approach creates valuable quality assurance records while enabling performance tracking over time. Advanced facilities sometimes employ colorimetry equipment for objective, precise measurements when absolute accuracy is non-negotiable.

When weld colors signal unacceptable oxidation levels, remediation becomes necessary. Your cleaning approach should match the oxidation severity:

-

Light Oxidation: Can often be addressed with mechanical cleaning using stainless steel brushes or non-contaminating abrasives.

-

Severe Oxidation: May require chemical passivation or electro polishing to restore optimal corrosion resistance.

Final Thoughts on Weld Colors and Quality

Mastering oxidation prevention and remediation is an important skill for welding professionals. Through disciplined heat control, strategic shielding gas application, and unwavering attention to cleanliness, welders can consistently deliver high-quality welds that excel in the most demanding environments.