What is Scuba Welding?

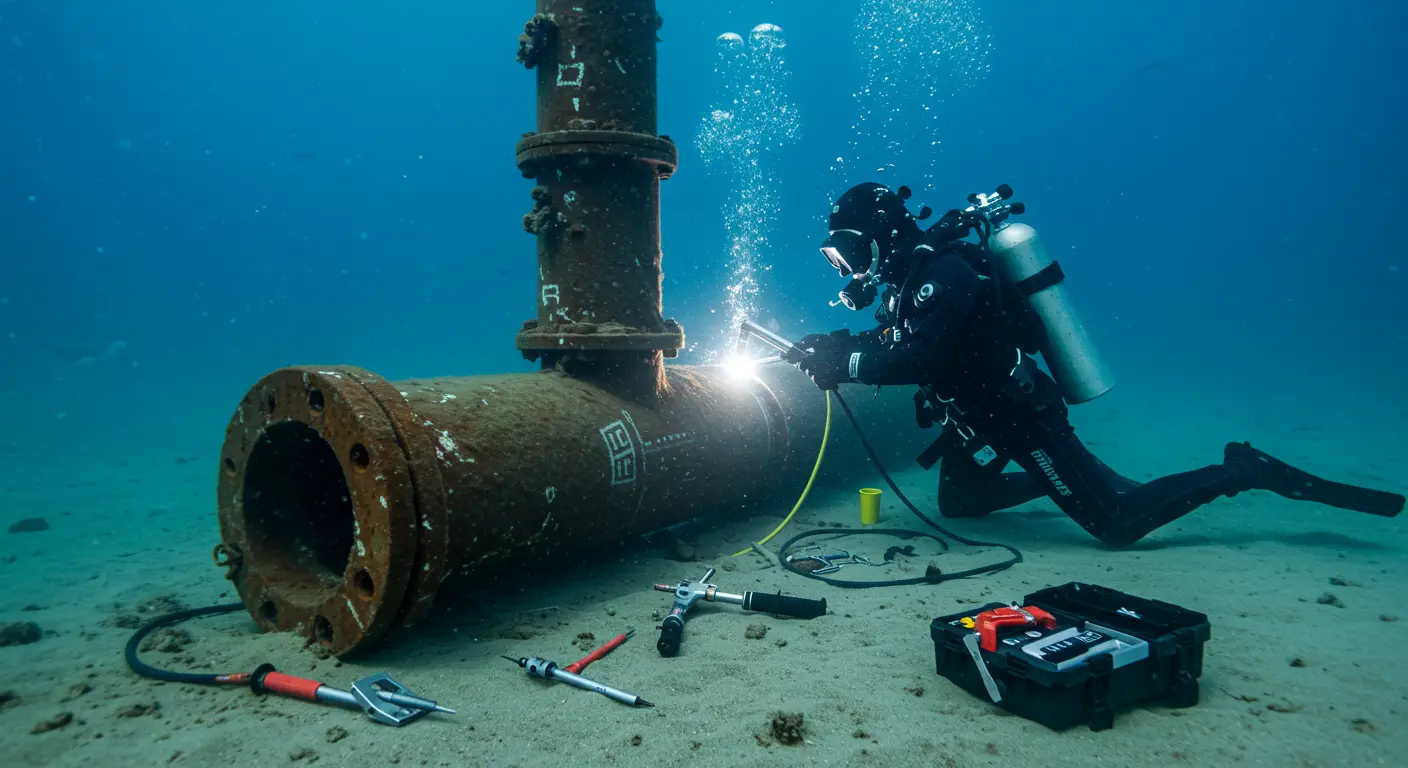

Scuba welding—more accurately termed underwater welding—marries the precision of metallurgy with the raw physicality of commercial diving. These specialized professionals execute welds in submerged environments, confronting significant water pressure, murky visibility, and the ever-present danger of electricity meeting water.

This demanding profession requires mastery of both welding techniques and diving protocols. Their work is essential for maintaining and repairing critical infrastructure that cannot be easily moved to the surface, including:

-

Offshore oil rigs

-

Pipelines

-

Ships and submarines

-

Dams

-

Underwater habitats

Due to the inherent dangers and specialized skills required, underwater welding ranks among the world’s most dangerous occupations. Yet for those who survive the intensive training, it delivers exceptional financial rewards.

Types of Underwater Welding Techniques

Underwater welding splits into two fundamental approaches: wet welding and dry welding. Each method offers distinct advantages, inherent limitations, and ideal applications depending on project demands and environmental conditions.

| Feature | Wet Welding | Dry Welding (Hyperbaric) |

|—|—|—|

| Environment | Performed directly in the water | Conducted in a dry, pressurized chamber |

| Quality | Lower; prone to defects from rapid cooling | High; comparable to surface welds |

| Speed & Cost | Faster and more cost-effective | Slower, more complex, and expensive |

| Common Use | Temporary or non-structural repairs | High-integrity, critical structural welds |

Beyond these two categories, specific underwater welding processes include:

-

Shielded Metal Arc Welding (SAW or stick welding)

-

Gas Metal Arc Welding (GMA or MIG)

-

Tungsten Inert Gas Welding (TIG/GTA)

-

Fusion welding

Wet Welding Processes

Shielded Metal Arc Welding (SAW)—commonly called stick welding—is the primary method for wet welding. This technique employs waterproof electrodes with specialized coatings that generate a protective gas bubble around the arc, effectively pushing water away to enable weld formation.

Wet welding requires specialized equipment: high-amperage power supplies, waterproof electrode holders, and meticulously insulated cables. The welder-diver dons standard commercial diving gear augmented with additional protective equipment to deflect the arc’s intense heat, flying sparks, and harmful UV radiation.

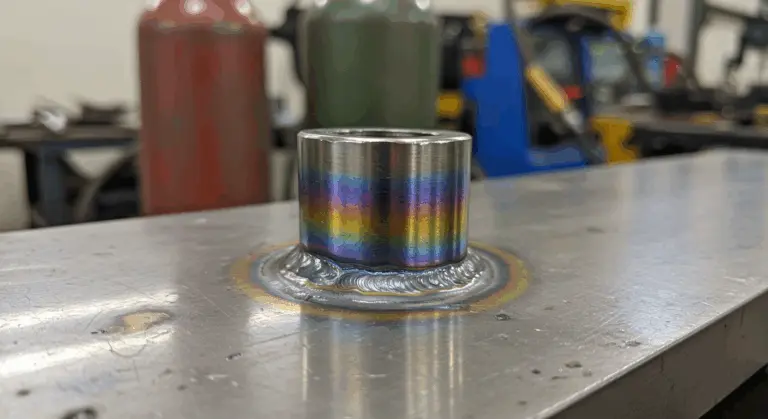

Despite its advantages in mobility and execution speed, wet welding has significant limitations. The surrounding water’s rapid cooling effect can induce excessive hardness and cracking in the weld zone.

Dry Welding Chambers and Processes

Dry welding takes place in specialized enclosures engineered to exclude water entirely. The primary configurations include:

These controlled dry environments allow for advanced welding techniques that deliver superior weld quality—TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and plasma arc welding among them.

Risks and Hazards of Scuba Welding

The fusion of diving and welding hazards creates an extremely dangerous work environment that requires strict safety protocols and constant vigilance.

Electrical shock is the primary danger, given water’s exceptional conductivity. Compounding this danger, the welding process generates hydrogen and oxygen gases that can accumulate into explosive pockets within confined spaces.

Diving-specific hazards include equipment failures that can lead to drowning, plus decompression sickness—the dreaded “bends”—resulting from improper ascent procedures. Chronic exposure to pressure variations can inflict lasting damage to ears, lungs, and sinuses.

The welding process brings additional hazards: toxic fume inhalation, burns from molten metal splatter, and tissue damage from intense ultraviolet radiation. Environmental hazards layer additional risks—powerful currents, zero visibility conditions, and marine life interference.

Specific technical challenges that can compromise weld quality include:

-

Obscured visibility from gas bubbles

-

Disturbed weld pools

-

Rapid cooling of joints, leading to defects

Training and Certification for Underwater Welders

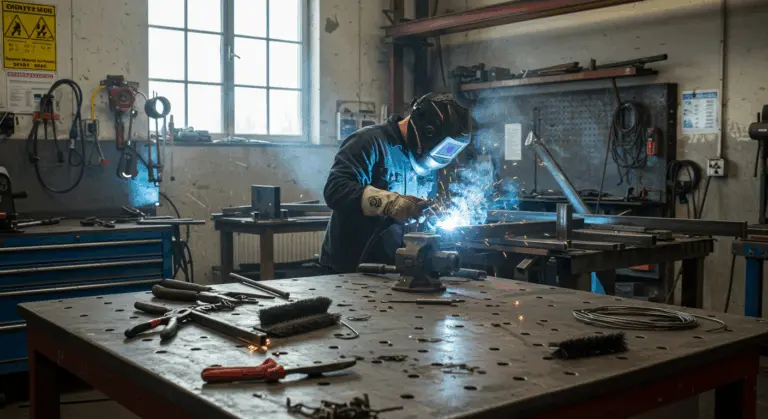

The path to becoming a certified underwater welder requires extensive training that combines surface welding mastery with commercial diving expertise. Most professionals start by establishing a solid foundation in conventional welding through vocational programs or apprenticeships, earning commercial welder certification.

Next comes commercial diving training from an accredited institution, covering essential skills such as:

-

Diving physics and physiology

-

Underwater navigation

-

Decompression procedures

-

Emergency protocols

-

Equipment operation and maintenance

The physical requirements are demanding—candidates must demonstrate exceptional swimming ability and possess the endurance to withstand crushing ocean pressures and unpredictable currents.

Once both welding and diving certifications are secured, aspiring underwater welders must complete specialized integration training. Programs like the Underwater Welding Certificate or comprehensive Commercial Diving with Underwater Welding courses teach the unique techniques, specialized tools, and critical safety protocols specific to subaquatic operations.

Professional certification typically aligns with standards established by the American Welding Society (AWS) and the Association of Diving Contractors International (ADC). Continuing education is essential, with many professionals pursuing specialized certifications to advance their careers:

Career Opportunities and Salary Expectations

Underwater welders discover varied career paths across multiple critical industries:

Compensation reflects the high risks and specialized expertise. Entry-level positions typically command $50,000 to $80,000 annually, while seasoned professionals can exceed $200,000.

Employment structures within the industry vary considerably. Many underwater welders operate as independent contractors, migrating between projects while potentially facing income gaps between assignments. This arrangement often delivers premium pay rates but sacrifices benefits and job security.

The career outlook looks strong, driven by global infrastructure expansion and the perpetual maintenance demands of existing underwater structures. The relatively small pool of individuals capable of completing the demanding training improves employment prospects for successful candidates.

Conclusion: The Future of Scuba Welding

Scuba welding continues to be essential for maintaining our planet’s marine infrastructure. As offshore energy projects, global shipping, and coastal development accelerate, demand for skilled underwater welders will intensify to preserve the structural integrity of subsea installations.

New technology is transforming the field, improving both safety margins and weld quality. Enhanced hyperbaric chamber designs enable more efficient dry welding operations, while emerging automated and remotely operated welding systems are starting to supplement traditional diver-welders in select applications.

Safety protocols are constantly improving as industry organizations and regulatory authorities adopt stricter standards for training, equipment specifications, and operational procedures. These enhancements, coupled with deeper insights into diving physiology and welding metallurgy, are reducing occupational hazards.

Though the training is challenging, and the work remains hazardous, underwater welding offers excellent career opportunities for technically gifted individuals who thrive in extreme environments.