What Is Sanitary Welding?

Sanitary welding—also known as hygienic welding—represents a specialized fusion process designed for joining metal components where cleanliness and sterility are paramount. This technique is primarily used in manufacturing and assembling sanitary stainless steel components across several demanding sectors:

Sanitary welding differs from conventional methods through its ability to create joints that are simultaneously robust, leak-proof, and remarkably smooth. These crevice-free surfaces are essential for preventing bacterial colonization while facilitating effortless cleaning—qualities that are non-negotiable in sensitive applications.

In regulated industries, these welds are critically important. They must demonstrate exceptional corrosion resistance, maintain a minimal profile, and endure the rigors of intensive cleaning and sterilization protocols.

Creating high-quality sanitary welds requires specialized techniques, materials, and strict process control to meet the stringent safety and quality standards of regulatory agencies.

Applications of Sanitary Welding

Manufacturing uses sanitary welding for stainless steel process piping, integrated systems, and bespoke fabrications. These applications often require purged pipe welding to ensure internal cleanliness, coupled with specialized surface finishing techniques.

This technique is essential for equipment that directly contacts sensitive products or requires frequent sterilization, including vats, tanks, and transfer piping—all designed to protect product purity.

Food-Grade Applications

Within the food and beverage sector, sanitary welding is fundamental to consumer safety and product excellence. It ensures equipment actively prevents contamination while enabling thorough, effective cleaning protocols.

Food-grade sanitary welds demand full penetration and smooth, crevice-free finishes to prevent bacterial growth. They are essential in constructing equipment such as:

-

Processing vessels

-

Storage tanks

-

Transfer piping

-

Mixing equipment

-

Packaging machinery

Dairy processing operations face particularly stringent requirements—equipment must seamlessly handle both raw and pasteurized products without risking cross-contamination. Breweries and beverage producers also depend on sanitary welding to preserve both product purity and flavor integrity.

Commercial kitchen equipment presents another critical application area. Food preparation surfaces and sinks incorporate sanitary welds to create seamless joints that withstand aggressive cleaning regimens while preventing food particle accumulation—a fundamental requirement for maintaining hygiene standards in food service environments.

Pharmaceutical Industry Uses

The pharmaceutical industry operates under extremely strict standards, driven by strict regulatory oversight and the critical nature of drug manufacturing. Sanitary welding must meet the highest quality standards to ensure contamination-free environments—a prerequisite for maintaining both product purity and therapeutic efficacy.

Pharmaceutical piping systems are a key application, transporting chemicals and products through networks that must remain absolutely free of defects capable of harboring bacteria. Stainless steel dominates material selection, valued for its superior corrosion resistance and inherent hygienic properties.

Biopharmaceutical facilities use sanitary welded equipment in vaccine production, bioprocessing, and sterile filling operations. This specialized equipment must maintain sterility throughout extended production runs while withstanding both cleaning-in-place (CIP) and sterilization-in-place (SIP) procedures.

Specialized techniques such as orbital welding and rigorous weld purging protocols have become standard practice within pharmaceutical applications. These methods ensure consistent quality while maintaining compliance with Good Manufacturing Practices (GMP).

Medical Industry Applications

Medical industry applications demand sanitary welding for creating instruments and equipment where patient safety is critical. Here, exceptional cleanliness, precision, and reliability aren’t just preferred—they’re absolutely essential.

Surgical instruments present particularly demanding requirements. These tools need smooth, crevice-free welds capable of enduring repeated sterilization cycles without degradation. This ensures every instrument—from basic forceps to sophisticated laparoscopic devices—remains free from contamination risks.

Medical implants, including orthopedic and cardiovascular devices, depend on high-quality welds for seamless integration with human tissue. These welds must demonstrate biocompatibility, corrosion resistance, and maintain a low profile to minimize rejection risks while ensuring optimal function.

Laboratory equipment such as sterilizers and centrifuges also relies on sanitary welding to preserve sterile conditions essential for sensitive research applications. The precision inherent in TIG welding makes it ideal for the intricate components found in advanced medical equipment, ensuring both performance excellence and regulatory compliance.

Sanitary Welding Techniques

Creating high-quality sanitary welds demands specialized techniques that ensure joints are smooth, fully penetrated, and completely free from defects that might harbor bacteria or contaminants. These sophisticated techniques have evolved specifically to satisfy the stringent requirements of industries where hygiene and product purity are essential.

Effective sanitary welding depends on meticulous preparation, rigorous process control, and choosing the right technique for each specific application. Surfaces must undergo thorough cleaning before welding begins—any contamination could severely compromise the final product’s quality and hygienic integrity.

TIG Welding for Sanitary Purposes

TIG (Tungsten Inert Gas) welding, also known as GTA, is the preferred method for sanitary applications. It offers unmatched precision, exceptional cleanliness, and superior heat control—all critical factors for achieving high-quality results.

During sanitary TIG welding, a non-consumable tungsten electrode generates an arc that melts the base metals. Simultaneously, an inert gas shield—typically high-purity argon—protects the weld pool from atmospheric contamination.

Orbital TIG welding is an advanced, automated version where the welding head rotates around a fixed pipe. This process produces consistent, high-quality welds around the entire joint while minimizing human error.

Autogenous TIG welding—which employs no filler material—works well for applications requiring minimal heat input and superior finish quality. It produces welds with minimal disruption to the base material, making it perfect for thin-walled tubing and sensitive medical or pharmaceutical components.

Surface Finishing in Sanitary Welding

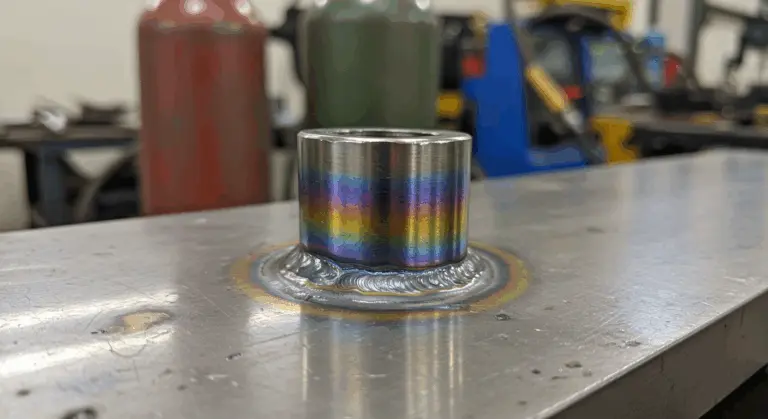

Surface finishing is a crucial step, converting raw welds into smooth, non-porous surfaces that actively prevent bacterial growth. The quality of this finish directly impacts both the component’s hygienic properties and its cleanability.

Mirror polishing employs progressively finer abrasives to achieve a smooth, reflective finish (reaching as low as 0.2μm Ra). This ultra-smooth surface dramatically minimizes bacterial adhesion while simplifying cleaning procedures.

Electro polishing utilizes an electrochemical process to remove microscopic peaks from the metal surface, leaving behind a smooth, passive, and highly corrosion-resistant layer. This technique is particularly useful for complex geometries and internal surfaces that mechanical methods cannot easily reach.

Mechanical methods—including grinding, sanding, and buffing—are often used as preliminary steps. These processes remove discoloration, excess material, and visible flaws before more refined finishing techniques are applied to achieve final roughness specifications.

Proper surface finishing provides two key benefits: it enhances the hygienic properties of sanitary welds while simultaneously improving their mechanical performance by reducing stress concentrations and boosting fatigue resistance. In industries where both cleanliness and durability are essential, high-quality surface finishing is essential in product quality and safety.

Standards and Guidelines for Sanitary Welding

Comprehensive standards govern sanitary welding practices, establishing quality and safety benchmarks that manufacturers must meet. These detailed guidelines specify material requirements, process parameters, and inspection criteria necessary for regulatory compliance.

The American Welding Society (AWS) D18 series provides detailed standards for sanitary welding procedures, qualifications, and acceptance criteria. Key standards include:

-

AWS D18.1: Covers austenitic stainless steel piping and tubing for the food and beverage industry.

-

AWS D18.2: Pertains to sanitary vessels and equipment.

-

AWS D18.3: Addresses welding for pharmaceutical applications.

The 3-A Sanitary Standards offer additional guidance, particularly for dairy and food processing operations. These standards establish design criteria focused on cleanability and contamination prevention—the 3-A symbol on equipment serves as a mark of compliance.

Within pharmaceutical and bioprocessing sectors, the ASHE BPE (Bioprocessing Equipment) standard provides detailed requirements for hygienic welding. It encompasses technical specifications, documentation protocols, material traceability, and surface finish requirements critical for validated environments.

International standards such as ISO 14159 and ISO 22000 further shape sanitary welding practices by establishing hygiene requirements for machinery design and food safety management systems, respectively. Adherence to these standards helps ensure welded components satisfy global requirements for cleanliness and product safety.

Inspection and Quality Control in Sanitary Welding

Rigorous inspection and quality control protocols help ensure sanitary welds satisfy stringent requirements for strength, integrity, and hygiene. These comprehensive protocols identify defects that could potentially compromise safety or performance.

Visual inspection is the first quality control step. Inspectors meticulously examine welds for proper penetration, smooth tie-ins, and complete freedom from defects like cracks or porosity.

Non-destructive testing (NDT) methods reveal more about weld quality:

-

Radiographic Testing: Uses X-rays or gamma rays to reveal internal defects like incomplete fusion or voids.

-

Ultrasonic Testing: Employs sound waves to detect subsurface flaws.

-

Liquid Penetrant Testing: Identifies surface-breaking defects invisible to the naked eye.

Critical pharmaceutical and medical applications require comprehensive documentation of inspection results for quality control purposes. These detailed records provide essential traceability and compliance proof, typically including photographs, measurement data, and inspector certifications.

Horoscopic inspection is important for examining the internal surfaces of welded pipes and vessels. Using specialized optical instruments, this technique enables visual inspection of otherwise inaccessible areas, ensuring internal surfaces meet the same exacting standards as external ones—a vital requirement for maintaining product quality.