What is Pipe Welding? – Overview and Importance

Pipe welding represents a specialized fusion technique for joining two pipes together. This process is essential for ensuring the longevity, structural integrity, and operational safety of piping systems across numerous industries, commonly using advanced arc welding methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas).

A fundamental distinction separates pipe welding from pipeline welding. Pipe welding typically involves crafting complex pipe assemblies within industrial facilities like refineries, where components must endure extreme operational conditions. Pipeline welding, conversely, focuses on establishing extensive, uniform distribution networks that transport vital resources—gas, water, and oil—across tremendous distances.

Quality pipe welding is vital. These critical connections must preserve structural integrity under diverse pressures, temperatures, and environmental stresses. A single joint failure can trigger catastrophic consequences: environmental devastation, substantial production losses, and severe safety hazards. This makes pipe welding a critical safety requirement in modern industrial operations.

Pipe Welding Techniques – Understanding the Methods

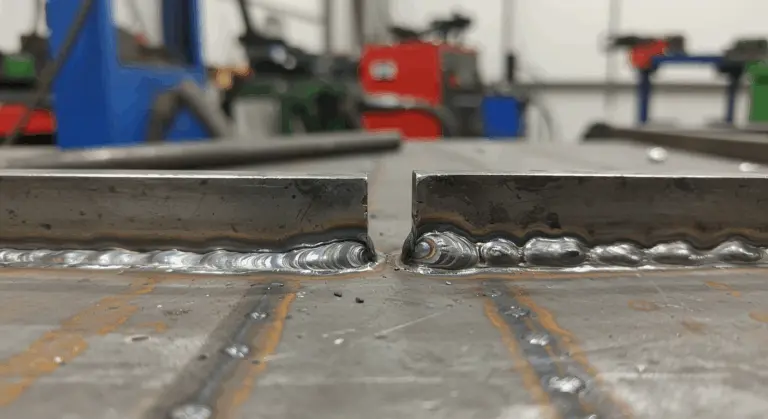

Pipe welding encompasses numerous specialized techniques, making proper method selection crucial for project success. Skilled welders must master various metal transfer approaches while developing proficiency in critical joint preparation—including precise beveling and cutting techniques.

Selecting the optimal welding technique hinges on multiple critical factors, since each method delivers distinct levels of penetration, structural strength, and surface finish quality. Key considerations include:

-

Pipe Material and Thickness

-

Welding Position

-

Intended Application

-

Environmental Conditions

-

Accessibility to the Weld Area

Modern pipe welding has evolved significantly, now incorporating both manual craftsmanship and sophisticated automated processes. New technologies continue to improve precision, operational efficiency, and quality control standards. Here are the most common pipe welding techniques used today.

Shielded Metal Arc Welding (SAW) – Key Features

Shielded Metal Arc Welding (SAW)—commonly dubbed “stick welding”—stands as one of the most versatile and extensively utilized pipe welding techniques. This method employs a flux-coated consumable electrode rod that melts when electric current generates an arc between the rod and base material. During welding, the flux coating disintegrates, producing a protective shielding gas that safeguards the weld area from atmospheric contamination while forming a slag layer over the weld bead.

SAW offers several key advantages:

-

Portability: It requires minimal equipment, making it highly portable and ideal for field work.

-

Versatility: The process is effective in various environmental conditions and can be used on dirty or rusty materials.

-

Cost-Effectiveness: It is a relatively inexpensive welding method.

SAW does have some limitations. The process operates slower than alternative methods since welders must frequently pause to replace consumed electrodes. It demands considerable operator expertise, particularly for challenging overhead or vertical positions. While SAW produces strong, reliable joints, it may not deliver the cleanest or most aesthetically appealing welds.

Gas Metal Arc Welding (GMA) – Efficiency and Use Cases

Gas Metal Arc Welding (GMA)—more commonly known as MIG (Metal Inert Gas) welding—offers significant improvements in welding efficiency. This semi-automatic or fully automatic process utilizes a continuously fed consumable wire serving dual roles as both electrode and filler metal. GMA’s defining characteristic involves external shielding gas—typically argon, carbon dioxide, or specialized mixtures—that shields the weld pool from atmospheric contamination, producing exceptionally clean welds with minimal slag formation.

GMA’s efficiency stems from several factors:

-

Continuous Wire Feed: Eliminates the need to stop and replace electrodes, significantly increasing productivity.

-

High Deposition Rates: Allows for faster travel speeds compared to SAW.

-

Consistent Quality: The use of a constant voltage, direct-current power source provides reliable, high-quality welds.

GMA works best in manufacturing environments where speed and consistency are priorities. It’s extensively deployed in automobile manufacturing, fabrication shops, and large-scale industrial pipe installations. GMA proves particularly effective for welding thinner materials without burn-through while producing aesthetically superior welds requiring minimal cleanup. Though it may struggle in outdoor applications due to wind disrupting shielding gas coverage, its ease of learning, multi-metal compatibility, and automation potential make GMA a valuable technique in modern pipe welding operations.

Flux-Cored Arc Welding (FLAW) – Fast and Effective

Flux-Cored Arc Welding (FLAW)—sometimes called dual shield welding—was developed in the 1950s as an effective alternative to manual metal arc welding. This semi-automatic process utilizes equipment remarkably similar to GMA but with one critical distinction: instead of solid wire, FLAW employs a continuous-feed hollow electrode packed with flux. This design marries GMA’s speed with SAW’s versatility, creating an exceptionally efficient welding method.

FLAW comes in two primary variants:

-

Self-shielded: The flux within the wire generates its own protective gas, eliminating the need for an external gas cylinder and making it ideal for outdoor work.

-

Gas-shielded: Uses both internal flux and an external shielding gas for superior weld quality and additional protection in controlled environments.

FLAW excels in thick material applications, thanks to its impressive weld-metal deposition rate and robust penetration capabilities. FLAW performs exceptionally well in all positions and can effectively weld contaminated or dirty workpieces—a frequent challenge in field operations. These advantages have made FCA Was the go-to method for heavy-duty applications: manufacturing plants, bridge construction, heavy equipment repair, industrial piping, and railroad work. The process masterfully combines speed, portability, and weld strength, positioning it among today’s most versatile and effective pipe welding techniques.

Welding Positions for Pipes – Understanding Complexity

Welding positions for pipes present unique challenges that set apart pipe welding from other welding forms. Unlike straightforward flat plate welding, pipe welding frequently demands working in multiple positions simultaneously as the welder progresses around the pipe’s circumference. Learning these positions is important—each orientation presents distinct challenges involving gravity, accessibility, and joint configuration.

The industry recognizes several standardized pipe welding positions:

-

1G (Flat): The pipe is rotated while the welder remains stationary, making it the most accessible position.

-

2G (Horizontal): The pipe’s axis is vertical, and the welder works horizontally around it.

-

5G (Inclined Pipe): The pipe is fixed horizontally, forcing the welder to work in flat, vertical, and overhead positions.

The most demanding position? The 6G configuration, where pipes are fixed at a 45-degree angle. This position frequently appears in certification tests because it requires simultaneous mastery of all welding positions. Welders must continuously adapt their techniques for each weld section, and maintaining consistent quality throughout shows advanced skill and versatility.

Common Pipe Welding Issues – Challenges and Solutions

Pipe welding creates significant challenges that can severely compromise weld integrity if inadequately addressed:

Effective solutions begin with meticulous preparation and refined technique:

Advantages of Pipe Welding – Why It Matters

Pipe welding offers major benefits, making it the preferred joining method for critical piping systems. Its primary benefit lies in the exceptional strength and uniformity of welded joints, which create continuous metal structures that can match—or even exceed—the strength of the base pipe. This is essential for high-pressure or high-temperature applications.

Aesthetic appeal represents another compelling advantage. Smooth welds create seamless appearances far superior to mechanical joints with visible fasteners. Welded joints also demand less space than flanged or threaded connections, enabling more compact installations.

Welding is also highly versatile. Welding can join pipes of virtually any diameter, thickness, and material—from standard carbon steel to exotic alloys. Furthermore, welded joints eliminate potential leak paths inherent in mechanical connections, making them ideal for high-pressure systems or those transporting hazardous materials. The permanence and reliability of these joints streamline inspection processes, making pipe welding essential for critical infrastructure.

Pipe Welding Safety Precautions – Protecting Welders

Pipe welding involves multiple hazards requiring comprehensive safety measures. Personal protective equipment (PPE) forms the critical first line of defense. Welders must don flame-resistant clothing, heavy leather gloves, protective leather aprons or jackets, and cuffless pants to prevent hot metal entrapment. For overhead welding operations, additional protection—such as a bandana worn beneath the helmet—is strongly recommended.

Eye and face protection is essential. An auto-darkening welding helmet (shade #11 or darker) shields against dangerous arc flash, while impact-resistant safety glasses worn underneath guard against flying particles. Respiratory protection is equally vital, as welding generates harmful fumes. Proper ventilation remains essential, and in confined spaces, supplied-air respirators may become necessary.

Electrical safety demands constant vigilance, given that arc welding equipment operates with high voltage. Welders must ensure all equipment remains properly grounded, regularly inspect cables for damage, and never attempt welding in wet conditions. Fire prevention encompasses removing flammable materials, maintaining readily available fire extinguishers, and deploying fire watches when necessary. Comprehensive training and heightened awareness from the foundation for protecting welders and any nearby personnel.

Testing Methods for Welds – Ensuring Quality

Weld testing is necessary for verifying that connections meet stringent quality and safety standards. These evaluation methods fall into two primary categories, each serving distinct purposes in comprehensive quality assurance: non-destructive testing (NDT) and destructive testing.

Non-destructive testing (NDT) methods allow for weld inspection without damaging the pipe:

-

Visual Inspection: The most basic form, used to examine the weld for surface defects like cracks or porosity.

-

Radiographic Testing (RT): Uses X-rays or gamma rays to create images of the weld’s internal structure, revealing hidden defects.

-

Ultrasonic Testing (UT): Employs high-frequency sound waves to detect internal flaws like cracks and lack of fusion.

-

Magnetic Particle Testing (MT): Uses magnetic fields to reveal surface and near-surface defects in ferromagnetic materials.

-

Liquid Penetrant Testing (PT): Identifies surface-breaking defects by applying a liquid that seeps into cracks and is revealed by a developer.

The selection of appropriate testing methods depends on factors specified in standards like ISO 17635:2016, including quality requirements, material type and weld thickness, the specific welding process employed, and the extent of testing required. For critical applications, multiple complementary testing methods are frequently employed to ensure pipe welds maintain their structural integrity and fully comply with rigorous industry regulations.