Overview of New Welding Technologies

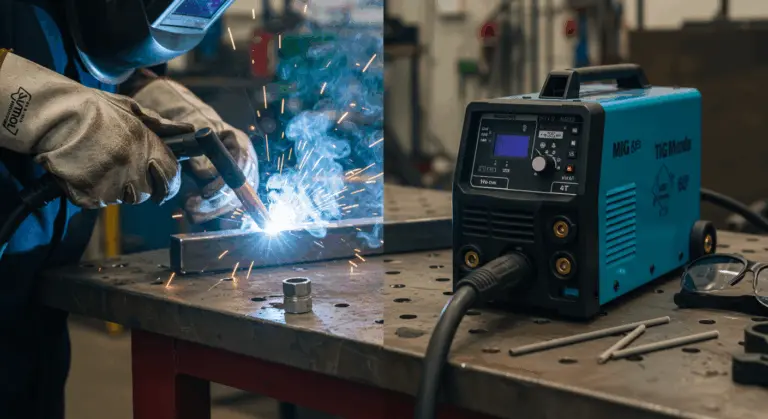

New technologies are transforming the welding landscape, transforming age-old processes with significant innovation. These advanced techniques are improving industry standards for both efficiency and precision:

Among these breakthroughs, laser welding stands out as a major advancement, offering clear advantages:

These technologies are changing manufacturing across critical sectors—automotive, aerospace, medical device production, and construction. Notably, As these advanced capabilities mature, they’re becoming increasingly accessible to smaller operations, democratizing what was once exclusive to large industrial giants.

Automation in Welding – The Rise of Robots

Automation is fundamentally reshaping welding, with robots and collaborative robots (robots) rapidly gaining ground in manufacturing environments. This shift is driven by The relentless pursuit of enhanced productivity, unwavering consistency, and improved safety. Currently, approximately 35% of welding job postings now actively seek professionals skilled in automated systems.

The Industry 4.0 revolution has accelerated welding automation through a combination of robotics, data analytics, AI, and cyber-physical systems. These technologies prove indispensable when handling delicate metals and executing complex tasks demanding high precision—making them the backbone of high-volume manufacturing operations.

Robotic solutions offer a strategic response to the skilled welder shortage while simultaneously meeting escalating production demands. Companies like Heretics are pioneering accessibility in automation. Several important trends are emerging:

Robotic Welding Systems – Enhancing Precision

In large-scale manufacturing, robotic welding systems have become essential tools, executing intricate tasks with extraordinary accuracy and unwavering repeatability. The integration of AI enhances their capabilities, enabling real-time adjustments that optimize quality under constantly shifting conditions.

Robotic welding delivers significant benefits across multiple dimensions:

Robot Welding – Collaboration with Humans

Collaborative robots (robots) represent an important advance in welding automation—engineered to work harmoniously alongside humans within shared workspaces. Unlike traditional industrial robots, Advanced sensors enable barrier-free operation, creating effective collaboration that marries robotic precision with human expertise and adaptability.

Robots excel at shouldering repetitive or physically demanding welding tasks, liberating human welders to concentrate on fabrication’s more complex dimensions—those requiring seasoned judgment and experience.

Welding robots have significantly changed workplace dynamics across countless fabrication shops. Human welders now function as operators and supervisors of these collaborative machines, leveraging their expertise for programming, quality control, and tackling the most intricate welding challenges.

AI and Data Analytics in Welding

Artificial intelligence is significantly improving welding through several key capabilities:

Smart sensors and data analytics are providing welders with valuable operational insights. Through continuous data collection and processing from each weld, these technologies enable early problem identification and process optimization. Real-time adjustments become possible, while historical analysis unveils patterns that drive overall efficiency improvements.

Advanced technology is improving AI-supported processes like laser beam welding, where sophisticated control systems precisely modulate beam characteristics. In mission-critical sectors—aerospace and medical manufacturing—data-driven quality control now delivers comprehensive documentation of weld integrity.

Sustainable Practices in Welding Technology

Sustainability is no longer optional in welding—it’s becoming a business necessity. The industry is rapidly embracing practices that slash environmental impact while maintaining or even enhancing performance. Modern sustainable welding approaches prioritize eco-friendly materials and energy-efficient methods that minimize resource consumption and waste generation.

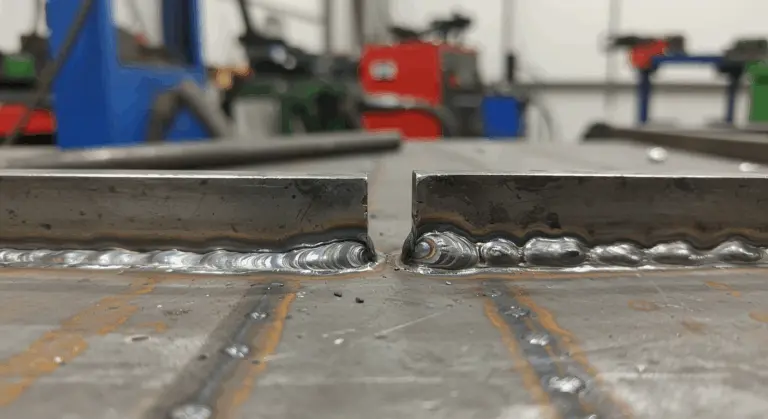

Advanced techniques like friction stir welding and laser welding demonstrate these sustainable benefits. Friction stir welding creates robust joints through mechanical friction rather than melting, dramatically reducing energy consumption compared to traditional arc welding.

Innovative surfacing technology represents another sustainable advance, eliminating external shielding gases in specific applications. This advancement enhances portability while reducing the environmental footprint tied to gas production and transportation.

Training and Development for Welders

Welding technology’s rapid evolution demands comprehensive training programs that connect traditional skills and the expertise required for advanced equipment. These initiatives prove essential for developing technicians and engineers proficient with both manual and automated systems.

Training on cutting-edge tools and technologies provides welders with important competitive advantages in today’s dynamic job market. Professionals who master the latest welding innovations discover expanded career opportunities and enhanced job security.

Welders can advance their careers through multiple strategic pathways, supported by tailored training programs utilizing diverse delivery methods:

VR/AR Training – The Future of Welding Education

Virtual and augmented reality (VR/AR) are transforming welding education through immersive training environments that deliver significant benefits:

Professionals can maintain their competitive edge by actively participating in workshops, seminars, and industry conferences. The future of welding education will be characterized by increasingly sophisticated, AI-driven VR/AR systems that deliver adaptive learning experiences tailored to individual needs.

Conclusion – The Future of Welding Technology

The future of welding is shaped by the convergence of automation, AI, advanced materials, and immersive training technologies. These innovations are creating new levels of precision, efficiency, and safety. As these technologies mature and become increasingly integrated, they will continue redefining the very possibilities of material joining and fabrication across every industry sector.