Understanding Vertical MIG Welding Techniques

Gravity presents the fundamental challenge in vertical MIG welding, constantly pulling molten metal downward and threatening to create unsightly drips or sagging beads. Mastering this position demands strategic adjustments to your technique—turning potential frustration into strong, visually striking welds.

This challenging position requires precise control in controlling travel speed, torch angle, and heat input to defy gravity’s pull. Most vertical MIG welding ascends uphill, delivering superior penetration and quality. However, the downhill approach serves thinner materials well.

Success in vertical MIG welding depends on mastering advanced torch manipulation techniques. While flat welding may forgive a simple straight bead, vertical welding demands intricate weaving patterns that control the weld pool effectively. These patterns help distribute heat evenly and prevent the molten metal from running ahead of your weld.

Triangle and Upside-Down V Motions

Two of the most effective motion patterns for vertical MIG welding are the triangle and upside-down V techniques. These patterns help control the weld pool while ensuring proper fusion at the joint edges.

The triangle motion moves your torch in a triangular pattern as you climb upward. Begin at one joint edge, sweep across to the opposite side, then ascend slightly before returning to your starting side at an elevated position. This methodical stacking pattern builds your weld bead systematically while allowing time for cooling.

The upside-down V technique—sometimes dubbed the inverted V—works very well for vertical welding challenges. Start by establishing fusion on both joint edges at your weld’s base, then drive into the center while ascending slightly, creating that distinctive upside-down V pattern. This technique ensures good fusion on both sides of the joint while controlling the weld pool’s movement. The momentary pause at each side allows the weld to cool slightly, preventing excessive sagging while maintaining proper penetration.

Both techniques require consistent practice to master their intricate timing and rhythm. Success lies in developing muscle memory for these patterns while staying aware of how your weld pool responds to each deliberate movement.

Controlling the Weld Pool

Weld pool control is the most important skill in vertical MIG welding—it’s your primary defense against sagging and your pathway to exceptional finish quality.

Several strategies help maintain puddle control. First, dial in precise welding parameters—voltage and wire feed speed must work together to create the right heat for your specific material thickness. Too much heat causes excessive fluidity in the weld pool, while too little prevents proper fusion.

Travel speed is crucial—crawling too slowly allows the puddle to grow too large and sag, while racing ahead starves the joint of proper fusion and invites cold lap defects.

Consistent weaving motion serves multiple functions for puddle control, serving several vital functions:

-

Manages Heat: It distributes thermal energy across a wider area.

-

Ensures Fusion: It promotes a strong bond at both edges of the joint.

-

Prevents Sagging: It allows momentary cooling as you move from side to side.

This technique produces a stable, consistent weld bead with excellent appearance and structural integrity.

Interestingly: thicker steel often yields a more manageable weld pool than its thinner counterparts. The increased mass helps stabilize the puddle, making it easier to add filler metal consistently. Many welders find that once they develop confidence with thicker materials, their overall vertical welding skills improve significantly.

Remember that masterful weld pool control has an additional benefit—it minimizes warping and distortion by strategically managing heat input. The goal is to find the right balance between achieving adequate penetration and preventing molten metal from outrunning your torch.

Essential Settings for Vertical MIG Welding

Proper machine settings are essential for successful vertical MIG welding. These settings will differ from those used in flat welding due to the need to manage heat input and prevent the weld pool from sagging under gravity’s influence.

Vertical MIG welding requires reducing your flat welding parameters—dial back both voltage and wire feed speed when tackling the same material. For quarter-inch steel paired with 0.030-inch wire, start with roughly 19 volts and 280 inches per minute wire speed. These parameters create a slightly cooler, more controllable weld pool that’s less prone to running or sagging.

Wire selection and shielding gas composition significantly affect your parameter choices. When using 75/25 (75% argon, 25% CO₂) with ER70S-6 wire, you’ll achieve a balance of penetration and control that works well for vertical welding. Pure CO₂ delivers aggressive penetration but creates more spatter and arc instability—a challenging combination for vertical work.

Inductance controls, when available, provide another way to adjust your arc characteristics. Higher inductance creates a softer arc with a wider, flatter bead profile that can be easier to control in the vertical position. Lower inductance produces a more focused, digging arc that may be beneficial for root passes.

Use these settings as a starting point. Always conduct test welds on scrap material matching your project’s thickness. Fine-tune parameters until you achieve good fusion, appropriate penetration, and a weld pool that obeys your commands throughout the entire vertical journey.

The Importance of the Root Pass

The root pass forms the foundation of your weld—its quality is particularly important in vertical welding. A masterfully executed root pass establishes the foundation for subsequent layers while ensuring your final weld’s structural integrity and strength.

In vertical applications, your root pass must achieve complete joint penetration while remaining utterly controllable—a delicate balancing act. This requires precise heat input and torch manipulation. The goal is to achieve complete fusion at the root without excessive penetration that could lead to burn-through or inadequate penetration that would create weakness.

During vertical root pass execution, focus on maintaining unwavering travel speed and weave consistency. The upside-down V technique works particularly well for root passes, as it ensures wetting into both sides of the joint while controlling the center penetration. Keep your arc length short and consistent to maintain control of the weld pool.

Thicker materials demanding beveled joints require precise root face and gap dimensions—the flat portion at your bevel’s base and the opening between pieces. Too large a gap makes the root pass difficult to control in the vertical position, while too small a gap may prevent adequate penetration.

Post-root pass inspection is essential—any defects will compromise your entire weld structure. Look for these key qualities:

-

Complete fusion at the root.

-

Consistent bead width.

-

Proper tie-in at the joint edges.

Ensuring a sound root pass saves time and prevents potential weld failures.

Tips for Successful Vertical MIG Welding

Mastering vertical MIG welding requires both dedicated practice and meticulous attention to detail. These proven tips will accelerate your skill development and deliver consistent, professional-grade results in vertical applications.

-

Understand the relationship: Learn how these three factors work together between voltage, wire feed speed, and travel speed. Practice on scrap material to develop your welding skills.

-

Listen to your arc: A healthy MIG weld produces that distinctive bacon-frying sound. When this soundtrack shifts, your technique or settings need adjustment.

-

Adjust Your Angles: A work angle of 5–15 degrees and a travel angle of 5–15 degrees are typical starting points, but be prepared to adjust them as you move along the joint.

-

Maintain the Weld Axis: Stay on your intended path to ensure even penetration and fusion. Use layout lines as a guide if necessary.

-

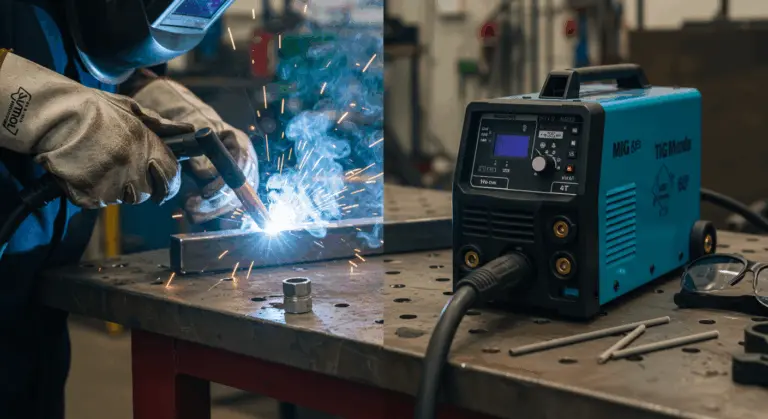

Use Appropriate Equipment: A pulsed or synergic MIG welder can simplify vertical welding by helping control the weld pool. Ensure your gun is rated for the required amperage.

-

Check Your Setup: Use the shortest practical cables, ensure a solid ground connection near the weld, and verify all connections are tight to maintain a stable arc.

-

Consult with Experts: Experienced welders can offer practical advice specific to your equipment and materials, accelerating your learning process.

Common Mistakes to Avoid

Even seasoned welders may encounter common problems when tackling vertical MIG welding. Recognizing these potential pitfalls helps you avoid them and elevate your results.

-

The Planning Trap: Plan your body position, torch angle, and sight lines before striking that first arc. Inadequate preparation leads to poor positioning and loss of control.

-

The Speed Demon: Vertical welding rewards patience and steady rhythm. Rushing results in poor penetration and fusion problems.

-

Using Excessive Heat: While tempting for penetration, too much heat makes the weld pool overly fluid and difficult to control. Start with cooler settings and adjust upward.

-

Inconsistent Travel Speed: This creates an uneven bead profile and inconsistent penetration. Focus on a steady pace.

-

Poor Torch Manipulation: Erratic weaves lead to uneven heat distribution. Practice your chosen pattern on scrap to develop muscle memory.

-

Poor Visibility: Ensure you can clearly see the arc and the leading edge of the weld pool. Use proper PPE and adequate lighting.

By avoiding these common mistakes and dedicating yourself to consistent technique development, you’ll see significant improvements in both your vertical MIG welding prowess and the quality of your finished work.