Understanding Welding – A Fusion Process

Welding represents a fundamental joining process where two or more pieces of metal or thermoplastics are fused together through the application of intense heat—typically from an electric arc that reaches temperatures around 6500°F. This arc melts the material surfaces and can be controlled either manually by skilled operators or guided through mechanical systems. As the heated materials gradually cool and solidify, they create a strong, unified joint whose properties closely mirror those of the original base materials.

Throughout the welding operation, electrodes frequently introduce filler metal to reinforce the joint’s strength. Protective measures are essential—shielding gas or slag create barriers that minimize air contact, preventing the oxidation and contamination that could compromise weld integrity. When the molten metals cool, they solidify into a metallurgical bond. This molecular-level connection ensures both structural integrity and long-term durability.

Difficult Metals to Weld – Unique Challenges

While welding is remarkably versatile as a joining method, certain metals present significant challenges due to their inherent material properties—particularly heat conductivity and oxidation tendencies. The metals most commonly recognized as difficult to weld include:

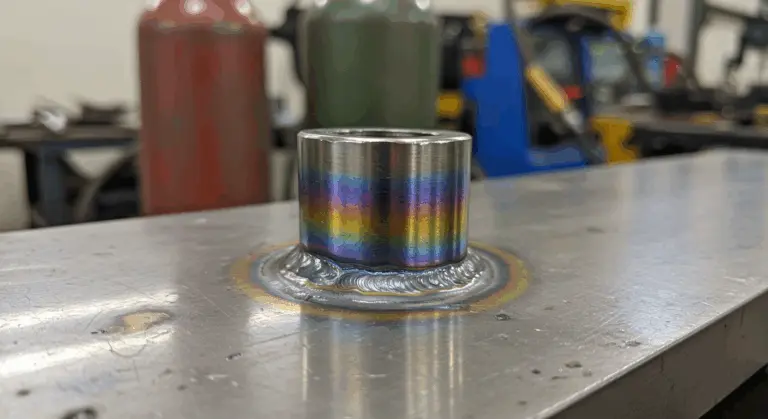

Titanium welding is notoriously difficult due to the metal’s aggressive reactivity with oxygen at elevated temperatures. Many seasoned professionals consider aluminum the most challenging material to truly master. Beyond these challenges, underwater hyperbaric welding represents the ultimate welding challenge—combining difficult materials with water pressure’s adverse effects and dramatically altered cooling rates that transform an already complex process into an extreme technical challenge.

Aluminum Welding – Complications and Solutions

Aluminum presents unique challenges that make it legendarily difficult among welders. Its exceptional thermal conductivity is the main problem—heat applied to one area spreads rapidly throughout the entire workpiece.

Aluminum’s strong attraction to oxygen creates another major obstacle. Upon air exposure, aluminum instantly develops a tough oxide layer melting at approximately 3700°F—nearly triple the base metal’s melting point of 1200°F. This oxide layer must be thoroughly removed before welding, yet reforms almost instantaneously after cleaning—creating a constant challenge for the welder. The oxide acts as a barrier that must be broken through for proper fusion to occur.

Most professionals use TIG or MIG welding for aluminum. Success requires careful attention to several factors:

-

Proper Cleaning: To remove the persistent oxide layer.

-

Appropriate Filler Metals: Must be compatible with the base alloy.

-

Correct Gas Shielding: To prevent atmospheric contamination.

-

Precise Heat Control: Often using higher amperage and faster travel speeds to prevent overheating.

Cast Iron Welding – Techniques and Precautions

Cast iron welding primarily involves repair work on existing castings rather than fabricating new structures from scratch. The predominant approach employs stick welding (SAW) with specialized nickel-based electrodes—either 99% nickel or 55% nickel alloys—specifically engineered to accommodate cast iron’s unique metallurgical properties.

Careful preparation is absolutely critical when tackling cast iron welding. Preheating the material to temperatures between 500-1200°F is often necessary to prevent thermal shock and reduce the formation of brittle structures in the heat-affected zone. Throughout the welding operation, heat input requires precise control to minimize cracking risks. Many professionals employ a technique of making short, staggered welds rather than continuous beads, allowing for gradual cooling and stress distribution.

Beyond standard welding precautions (e.g., protective clothing, helmets, ventilation), cast iron presents specific safety hazards:

-

Harmful Fumes: Heating can release carbon particles and potentially dangerous gases.

-

Cracking Risk: The material’s tendency to crack under thermal stress requires careful handling during welding and the slow, controlled cooling period.

Welding Techniques – Which Are the Hardest?

Among the arsenal of welding techniques available to modern fabricators, Tungsten Inert Gas (TIG) welding is widely considered the most difficult. This assessment has near-universal agreement across the welding community, though individual experiences naturally vary based on personal aptitude and training background.

TIG welding’s complexity emerges from requiring operators to orchestrate multiple actions in perfect harmony:

Regardless of the welding process employed, certain positions create their own unique challenges. Overhead welding is consistently the most challenging position—a constant fight against gravity combined with severely limited accessibility. Molten metal naturally wants to fall away from the joint, requiring the welder to maintain a shorter arc length and adjust travel speed accordingly. Combining overhead positioning with TIG welding creates an exponential skill requirement—the most difficult welding challenge.

TIG Welding – Mastering Precision

TIG welding stands out for its unmatched precision and control capabilities that other processes simply cannot rival. This technique allows welders to join extremely thin sections of metal with remarkable accuracy, often without burning through materials that would be impossible to weld using other methods. This exceptional control over heat input and weld pool dynamics allows craftsmen to produce welds that achieve both structural integrity and visual elegance—explaining TIG’s dominance in aerospace, automotive, and artistic metalwork applications where appearance matters.

TIG operations typically employ DEN (Direct Current Electrode Negative) configurations paired with high-frequency starts to eliminate tungsten contamination risks. Proper gas coverage is also critical, as disruptions in the inert shield can lead to porosity and weakened welds.

Common challenges in TIG welding include:

-

Achieving complete fusion without creating porosity.

-

Preventing cracking in heat-sensitive materials.

-

Maintaining consistent penetration throughout the joint.

High-Carbon Steel Welding – Risks and Techniques

High-carbon steel—containing 0.61% to 2.1% carbon—presents serious welding challenges rooted in its complex metallurgical behavior. Cracking represents the primary threat when welding these materials, triggered by martensite formation—an extremely hard yet brittle microstructure—within the heat-affected zone. This transformation happens when the material cools rapidly after welding, creating internal stresses that can lead to immediate cracking or delayed failure under load.

To mitigate these risks, several specialized techniques are essential:

-

Preheating: The material is preheated to reduce the cooling rate and minimize martensite formation.

-

Low-Hydrogen Processes: Using low-hydrogen electrodes and processes is strongly recommended to prevent hydrogen-induced cracking.

-

Filler Metal Selection: Filler metals must be specifically designed to accommodate the metallurgical changes in high-carbon steel.

Heat input control throughout the welding operation requires constant attention. Excessive heat can worsen the problems associated with rapid cooling, while insufficient heat may result in lack of fusion or incomplete penetration. These welding operations are significantly more time-consuming and resource-intensive than mild steel work, demanding skilled welders who understand the material’s temperamental behavior. Post-weld heat treatment is often necessary to relieve internal stresses and temper any martensite that may have formed. Without these precautions, welds in high-carbon steel are prone to failure, potentially resulting in costly repairs or dangerous structural compromises.

Welding Training – Preparing for Difficult Techniques

The learning process is multifaceted, encompassing both physical and technical hurdles:

Comprehensive training programs tackle both theoretical foundations and hands-on practical applications. They typically begin with simpler techniques and gradually progress to more challenging applications as students develop proficiency. This progressive methodology builds welder confidence while establishing transferable fundamental skills across diverse welding processes. For difficult techniques like TIG welding or challenging materials like aluminum and high-carbon steel, specialized training modules focus on the unique considerations and techniques required for success.

Continuing education is critically important in welding careers, especially as technologies and materials evolve rapidly. Training on new tools and techniques ensures welders remain competitive in the job market and prepares them for industry changes involving automation and data-driven quality control. Advanced certification in specialized welding processes significantly expands employment opportunities, particularly in high-paying sectors like aerospace, pressure vessel fabrication, and nuclear applications. Investment in mastering challenging welding techniques leads to enhanced career flexibility and substantially improved earning potential.

Common Mistakes in Welding – Avoiding Pitfalls

Even seasoned welders encounter significant challenges when tackling difficult techniques and demanding materials. Recognizing and avoiding common mistakes is essential for producing high-quality welds consistently. Inconsistent weld bead patterns often affect welders who maintain excessive travel speeds—reducing penetration and creating weak spots throughout the joint. Conversely, crawling too slowly introduces excessive heat input, causing warping, burn-through, or metallurgical changes that compromise base material integrity.

In TIG welding, several technical mistakes can compromise quality:

-

Long Arc Length: Reduces penetration and increases contamination risk.

-

Incorrect Torch Angle: Results in poor gas coverage or inadequate fusion.

-

Exposed Filler Rod: Contaminates the weld if the heated rod tip leaves the shielding gas envelope.

-

Inadequate Post-Flow: Allows oxygen to contaminate the weld pool before it solidifies.

Common structural defects include:

-

Undercut: A groove melted into the base metal at the weld’s edge, creating a stress point.

-

Porosity: Small holes or bubbles in the weld, typically from contamination or poor gas coverage.

-

Lack of Fusion: The weld metal fails to bond properly with the base material.

-

Cracking: A critical defect caused by stress, hydrogen embrittlement, or improper cooling rates.