Understanding Carbon Steel – Composition and Types

This carbon concentration dramatically shapes the steel’s behavior and weldability characteristics. Understanding this composition is essential for selecting appropriate welding techniques and achieving reliable, high-quality results.

Carbon steel is categorized into three main types based on its carbon content:

-

Low Carbon Steel (Mild Steel): Contains less than 0.3% carbon. It is the most common type and the easiest to weld due to its high ductility and formability.

-

Medium Carbon Steel: Contains between 0.3% and 0.6% carbon, offering a balance of strength and weldability.

-

High Carbon Steel: Contains more than 0.6% carbon. It provides superior hardness and wear resistance but is challenging to weld due to its susceptibility to cracking.

As carbon content climbs, steel gains hardness and strength but sacrifices ductility and weldability. This trade-off requires careful consideration in every carbon steel welding project.

Welding Techniques for Carbon Steel – An Overview

The optimal welding technique for carbon steel depends on its specific type, project requirements, and available equipment. The most common processes include:

-

Shielded Metal Arc Welding (SAW or stick welding)

-

Gas Metal Arc Welding (GMA or MIG welding)

-

Gas Tungsten Arc Welding (GTA or TIG welding)

-

Gas welding

Low carbon steel works well with virtually any common welding process. Its forgiving nature makes it ideal for beginners and versatile applications. However, as carbon content increases, welding becomes more challenging. Medium and high carbon steels generally require more specialized approaches, with low-hydrogen processes or low-hydrogen fillers being particularly important to prevent hydrogen-induced cracking.

When welding high carbon steel, several factors are critical:

-

Preheating: Reduces the cooling rate to minimize cracking risk.

-

Heat Input Control: Prevents excessive hardening in the heat-affected zone (HAZ).

-

Filler Metal Selection: Choosing a filler that matches or complements the base material is crucial for strong, defect-free welds.

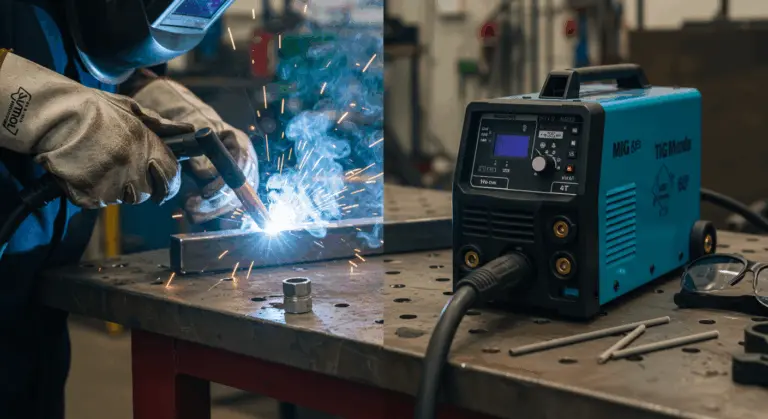

MIG Welding – Advantages and Applications

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMA), is a highly effective welding method for carbon steel. Its efficiency and versatility have made it indispensable across industries. This process employs a continuous solid wire electrode fed through a welding gun, paired with protective shielding gas that protects the weld pool from atmospheric contamination. This produces clean, strong welds with excellent appearance.

MIG welding offers several advantages for carbon steel:

-

Speed: It is significantly faster than many other processes, making it ideal for production environments.

-

Ease of Use: The process is relatively easy to learn and more forgiving than stick welding.

-

Quality: It produces consistent, high-quality welds with good strength, suitable for structural applications.

-

Control: It provides excellent control over heat input, preventing burn-through on thin materials.

MIG welding is used across diverse industries—manufacturing, construction, shipbuilding, and general fabrication. This combination of speed, quality, and cost-effectiveness has made it the go-to choice for professional shops and hobbyists alike.

TIG Welding – Precision and Control

Tungsten Inert Gas (TIG) welding, or Gas Tungsten Arc Welding (GTA), offers exceptional precision in carbon steel welding. This sophisticated process employs a non-consumable tungsten electrode to generate the arc while a separate filler rod is manually introduced into the weld pool. Argon, the typical shielding gas, creates a protective atmosphere around the weld zone. This separation of heat source and filler material gives welders excellent control over every aspect of the process.

The primary advantages of TIG welding for carbon steel are:

-

Exceptional Precision: It allows for highly accurate, clean welds with minimal spatter and distortion.

-

Low Heat Input: The process is ideal for welding thin sections of carbon steel without burn-through.

-

Aesthetic Finish: TIG produces visually appealing welds with no slag, often eliminating the need for post-weld cleanup.

However, TIG welding requires high skill and presents several challenges. Maintaining proper gas coverage to prevent contamination is essential. Preventing defects like porosity and cracking requires constant vigilance. Ensuring complete fusion between materials tests even experienced welders.

Stick Welding – Versatility and Use Cases

Stick welding, formerly known as Shielded Metal Arc Welding (SAW), is one of welding’s most enduring and adaptable processes. It excels particularly with carbon steel applications. This time-tested method employs a consumable electrode coated with flux to strike an electric arc between electrode and workpiece. As the electrode melts, it deposits metal into the joint while the flux performs double duty—creating a protective gas shield and forming a slag layer that guards the weld from atmospheric contamination.

Stick welding offers several advantages for carbon steel work:

-

Low Cost: The equipment is relatively inexpensive, making it accessible.

-

Versatility: It is effective on most metals, especially carbon steel.

-

Adaptability: It can be performed outdoors, in windy conditions, and in remote locations without a gas supply, making it ideal for field repairs and construction.

Stick welding is particularly useful for specific carbon steel applications. Outdoor and remote projects benefit from its portability. Thick materials—anything 1/8″ (3.2mm) or heavier—are well-suited for this process, making it indispensable for structural work. For maintenance and repair operations, its effectiveness combined with minimal equipment costs makes it an essential technique.

Preheating and Post-Weld Treatment – Best Practices

Preheating and post-weld heat treatment (PWHT) are essential when tackling medium and high carbon steels. These thermal treatments significantly effect over final weld quality and mechanical properties. They help prevent defects and ensure component longevity.

Preheating carbon steel before welding serves several important purposes. It slows the cooling rate of both weld and heat-affected zone (HAZ), dramatically reducing the formation of brittle microstructures that can cause cracking. Additionally, it helps expel hydrogen, significantly lowering hydrogen-induced cracking risks.

Post-weld heat treatment (PWHT) is equally important, involving controlled component reheating. It provides several benefits: relieving residual stresses that develop during welding, improving weld and HAZ microstructure, and enhancing mechanical properties like toughness and ductility. Common PWHT procedures for carbon steels encompass stress relief annealing, normalizing, and tempering—with parameters dictated by steel composition and thickness.

Common Welding Defects in Carbon Steel – Identification and Prevention

Welding defects in carbon steel can severely compromise joint integrity and performance. Understanding their root causes is key to prevention. Common defects include cracks, porosity, undercut and overlap, burn-through, spatter, underbilled welds or excess reinforcement, and distortion with misalignment.

Cracks are among welding’s most serious defects. They manifest in various forms—hot cracks, cold cracks, and crater cracks—typically stemming from high carbon content, rapid cooling rates, or excessive restraint during welding. Porosity presents as gas pockets or voids within the weld metal, usually triggered by contamination, inadequate gas shielding, or improper electrode handling.

Preventing these defects requires a systematic approach:

-

Material Preparation: Thoroughly clean the material to remove contaminants like oil, rust, and moisture.

-

Parameter Selection: Use the correct current, voltage, travel speed, and electrode type for the steel’s carbon content.

-

Thermal Management: For higher carbon steels, use preheating and control interpass temperatures to prevent cracking.

-

Proper Technique: Maintain the correct arc length, travel angle, and manipulation patterns.

-

Inspection: Use visual and non-destructive testing to identify defects early.

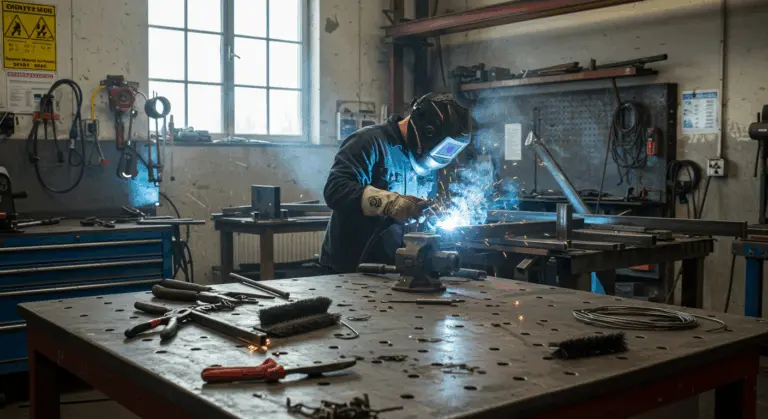

Safety Considerations for Carbon Steel Welding

Carbon steel welding presents numerous safety hazards requiring careful attention. Comprehensive safety protocols aren’t just recommended—they’re essential for protecting welders and personnel from serious harm.

Personal protective equipment (PPE) is the first line of defense:

-

Welding Helmet: An auto-darkening helmet with the appropriate shade rating to protect from arc flash.

-

Flame-Resistant Clothing: Prevents burns from sparks and spatter.

-

Leather Gloves: Shield hands from heat and sharp edges.

-

Safety Glasses: For eye protection when the helmet is raised.

-

Respiratory Protection: A respirator or proper ventilation system is crucial to avoid inhaling harmful fumes from metal oxides.

Beyond PPE, environmental safety measures are essential. Work area safety requires isolating the welding zone from flammable materials while keeping fire extinguishers within easy reach. Electrical safety demands proper equipment grounding and insulation to prevent potentially fatal electric shock.

Challenges in Welding High Carbon Steel

High carbon steel welding (above 0.6% carbon) presents significant challenges due to its exceptional hardenability. The intense heating and cooling cycle of welding can create extremely hard, brittle microstructures in the heat-affected zone (HAZ). This creates high cracking risks.

For example, consider: joining high carbon steel (like 1080 steel) to mild steel. The dramatic carbon content difference between these materials creates a weld zone with unpredictable properties. The high carbon component tends to form brittle martensite during cooling, while the weld must somehow maintain essential ductility for structural integrity.

Welding high carbon steel successfully requires specialized techniques. Thorough preheating—often to 250-350°C—slows cooling rates and reduces HAZ hardening. Low-hydrogen consumables and processes help prevent hydrogen-induced cracking. Controlled heat input minimizes brittle microstructure formation. Post-weld heat treatment (PWHT) through immediate tempering can relieve stress and reduce hardness.