Can You Stick Weld Aluminum?

Yes, you can stick weld aluminum, though it’s a challenging method with notable challenges. While far from ideal, it becomes possible with the right equipment and technique—making it useful for field repairs, maintaining thick aluminum sections, or when specialized equipment simply isn’t available.

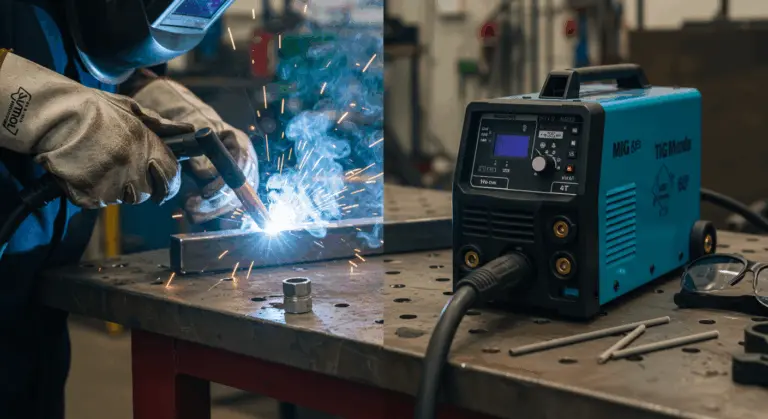

Stick welding machines for aluminum work without specialized features. The primary requirement? A welder with adjustable amperage to match electrode size and manufacturer’s recommendations.

This method works well for specific scenarios—substantial structural welds or as a faster, more economical alternative to TIG welding. However, the results are noticeably rough compared to TIG or MIG welding, rendering it unsuitable for visible or decorative work.

Stick welding isn’t recommended for aluminum less than 1/8″ thick due to burn-through risk. It’s best reserved for thicker, dirty sections or field conditions where maintaining cleanliness proves difficult.

Why Is Aluminum So Difficult To Weld?

Aluminum presents several unique challenges that make it particularly challenging to weld. Understanding these obstacles explains why specialized techniques and equipment are often preferred over stick welding for this challenging material.

The primary obstacle is aluminum’s persistent oxide layer that forms almost instantly on the surface. This oxide melts at approximately 3,700°F—nearly three times higher than the aluminum beneath it, which melts around 1,200°F.

Aluminum’s high thermal conductivity—about five times that of steel—further complicates welding. Heat dissipates rapidly from the weld zone, demanding higher amperage and making heat input very difficult to control.

Additional challenges include:

-

Softness and Heat Sensitivity: The metal can easily warp or burn through.

-

High Vulnerability to Contamination: Impurities readily cause weld porosity.

-

Difficult Arc Control: The insulating oxide layer complicates arc initiation and stability.

How To Stick Weld Aluminum

To stick weld aluminum, you need a standard DC welder, specific electrodes, and proper technique. While the results won’t match TIG or MIG refinement, it can be surprisingly effective for certain applications.

Aluminum Pieces Preparation

Proper preparation is essential for successful aluminum stick welding, as it directly impacts weld quality and helps overcome the metal’s inherent challenges.

Thoroughly clean all surfaces to remove contaminants like oil, grease, and the oxide layer—these contaminants cause porosity and weaken the weld. Use a dedicated stainless steel brush to avoid cross-contamination from steel.

Follow these cleaning steps:

-

Remove dirt, oil, and grease with an appropriate solvent.

-

Scrub the weld area with a dedicated stainless steel brush to remove the oxide layer.

-

Clean 1–2 inches beyond the weld zone on all sides.

-

Weld immediately after cleaning, as the oxide layer reforms quickly.

For thicker sections, preheating the aluminum to 200-300°F with a propane torch helps considerably. This improves electrode wetting and weld penetration noticeably.

Stick Electrode For Aluminum

Selecting the right electrode is essential for successful aluminum stick welding. Unlike standard steel electrodes, aluminum demands specialized stick electrodes designed specifically for its unique properties.

The most commonly recommended electrode is the E4043, which offers several advantages:

-

Provides a relatively steady arc.

-

Produces less spatter than other aluminum electrodes.

-

Works well in flat, horizontal, and vertical positions.

-

Typically requires 80 to 135 amps for 1/8″ diameter rods.

These electrodes, sometimes sold under brand names like “Alumina,” are highly susceptible to moisture. Store them in bone-dry conditions to prevent contamination and weld porosity.

When selecting your electrode size, 1/8″ (3.2mm) is the most common and versatile choice for general aluminum stick welding. These electrodes must be used with DEEP (Direct Current Electrode Positive, also called reverse polarity) for proper arc characteristics and penetration.

Aluminum electrodes cost more than steel ones, but using the correct type is non-negotiable. Standard steel electrodes simply won’t work on aluminum and may damage the material.

Check Your Stick Welder

Before attempting to stick weld aluminum, you should verify that your welder has the correct capabilities and settings. Not all stick welders are suitable for aluminum, and using the wrong setup causes problems and failed welds.

Your welder must support DC (Direct Current) output with DEEP (Direct Current Electrode Positive), or reverse polarity. This setting is required to break through aluminum’s oxide layer—AC or DEN (electrode negative) simply won’t work.

Ensure your machine provides precise amperage control, typically between 80 and 130 amps for a 1/8″ E4043 electrode. This adjustability is crucial for managing heat input and preventing defects.

Verify that your welder’s duty cycle is sufficient for the job at hand. Aluminum welding often requires higher amperage, which can push your machine toward its duty cycle limits.

Finally, ensure your ground clamp makes excellent contact with the workpiece. Aluminum’s oxide layer can interfere with electrical conductivity, so a clean, tight ground connection is needed for maintaining a stable arc.

Stick Aluminum Welding Technique

Mastering the technique for stick welding aluminum requires practice and an understanding of when this method is most appropriate. While often described as difficult and producing less attractive results, stick welding aluminum can be quite effective in specific situations.

• Harsh outdoor environments where wind might disrupt gas shielding

• Remote locations where portability is essential

• When working with heavier materials (1/8″ thickness or greater)

• For maintenance and repair tasks where appearance is secondary to functionality

• When cost considerations make other methods impractical

When executing the weld, maintain a slightly longer arc length than you would with steel—about 1/8″ to 3/16″. This helps prevent the electrode from sticking to the workpiece, which happens more frequently with aluminum due to its properties.

Move quickly along the joint with steady, consistent speed. Aluminum conducts heat rapidly, so dwelling too long in one spot can cause burn-through.

Strike the arc on a piece of scrap aluminum or on the joint itself—never on the surrounding work area, as this can cause contamination. Once the arc is established, maintain it carefully. Restarting an aluminum stick weld mid-joint is particularly challenging.

Finishing The Weld And Cleaning

Proper finishing and cleaning are crucial steps in the aluminum stick welding process, often requiring more effort than with other welding methods due to the significant slag and residue produced.

Allow the weld to cool slightly, then use a chipping hammer to carefully remove the slag, which comes off more easily while warm. Work methodically to avoid damaging the underlying weld.

After chipping, use a dedicated stainless steel wire brush to remove any remaining slag and prepare the weld for inspection. Using a brush previously used on steel will cause contamination.

Thorough post-weld cleaning is important to prevent corrosion and ensure weld integrity. While stick welding aluminum is messy, proper cleaning greatly improves the final result.

Potential Issues When Stick Welding Aluminum

Stick welding aluminum comes with several potential issues that welders should be aware of before attempting this challenging process. Understanding these problems can help set realistic expectations and potentially avoid some of the more common pitfalls.

The most noticeable issue is the poor aesthetic quality. Welds are often inconsistent and messy due to several factors:

-

Slag Inclusions: Slag can become trapped in the weld metal.

-

Excessive Spatter: Spatter adheres to the surrounding material and is difficult to remove.

-

Inconsistent Penetration: Maintaining a stable arc is challenging, leading to uneven penetration.

-

Stubborn Flux: The flux is difficult to remove completely, leaving a messy finish.

Another significant issue is that stick welded aluminum rarely passes certification codes for critical applications. The inherent inconsistency and potential for defects make this method unsuitable for structural applications where safety is paramount.

Alternatives to Stick Welding Aluminum

For most applications, MIG and TIG welding are superior alternatives to stick welding aluminum, offering cleaner, stronger, and more aesthetically pleasing results.

Each alternative has its own set of advantages and ideal use cases, which are explored in the following sections.

MIG Welding Aluminum

MIG (Metal Inert Gas) welding offers a significantly more effective approach to welding aluminum than stick welding for most applications. This process uses a continuously fed wire electrode and pure argon shielding gas to create clean, strong welds on aluminum.

The primary advantage of MIG welding aluminum is speed and efficiency. It’s much faster than TIG welding and produces cleaner results than stick welding.

However, MIG welding aluminum requires equipment modifications because the wire is much softer than steel:

-

U-shaped drive rollers to prevent crushing the wire.

-

Teflon or nylon torch liners to reduce friction.

-

Larger contact tips to accommodate the wire’s thermal expansion.

Most industrial aluminum MIG welding operations use a spool gun or push-pull system. A spool gun places a small spool of aluminum wire directly on the torch, eliminating the need to push the wire through long cable assemblies.

MIG welding aluminum requires a DC power supply set to electrode positive (DEEP) polarity. While the welds may not look quite as refined as TIG welds, they are significantly cleaner and more consistent than stick welds.

For those considering aluminum welding projects, investing in MIG equipment with aluminum capabilities will provide much better results than stick welding in almost all situations.

TIG Welding Aluminum

TIG (Tungsten Inert Gas) welding, also known as Gas Tungsten Arc Welding (GTA), is considered the best method for welding aluminum. This process offers unmatched precision, control, and weld quality, making it the first choice for professional aluminum fabrication when appearance and strength are critical.

TIG welding aluminum requires an AC (alternating current) power supply in most applications. The AC current provides a cleaning action during the electrode positive portion of the cycle, which helps break down the stubborn oxide layer on aluminum’s surface.

This two-handed technique, using a non-consumable tungsten electrode and a separate filler rod, offers several advantages:

-

Extremely precise control over heat input.

-

Ability to weld very thin aluminum (as thin as 0.020″).

-

Superior aesthetic quality with smooth, clean weld beads.

-

No spatter or slag to clean up.

-

Ideal for visible or cosmetic welds.

While standard TIG welding uses AC for aluminum, there are specialized techniques using DC TIG with helium shielding gas for thicker aluminum sections. This creates a hotter arc with deeper penetration but requires significant skill to execute properly.

The primary drawbacks of TIG welding aluminum are the slower speed compared to MIG welding and the higher skill level required. TIG welding has a steeper learning curve and demands good hand-eye coordination and torch control.

Despite these challenges, TIG welding is still the preferred method for aluminum welding, particularly for critical applications, thin materials, or any situation where weld quality and appearance are paramount.

When Is A Stick Preferred Over MIG And TIG Welding Aluminum?

Despite the clear advantages of MIG and TIG welding for most aluminum applications, there are specific scenarios where stick welding aluminum remains a practical or even preferred option. Understanding these situations helps welders make informed decisions about when to use this more challenging technique.

Stick welding aluminum is valuable in specific circumstances:

-

Field Repairs: Ideal for remote locations where portability is essential and shielding gas is unavailable.

-

Outdoor Conditions: Effective in windy environments that would disrupt MIG or TIG shielding gas.

-

Thick Materials: Advantageous for welding very thick sections (3/8″ and above).

-

Contaminated Surfaces: More forgiving on dirty or contaminated aluminum compared to the sensitive TIG process.

-

Budget Constraints: A practical option when the cost of specialized TIG or MIG equipment is prohibitive.

-

Emergency Use: Suitable for quick repairs where appearance is not a primary concern.

Stick welding’s equipment simplicity offers distinct advantages in harsh environments. A basic stick welder is more portable, requires no shielding gas cylinders, and generally has fewer components that could malfunction in challenging conditions.

While it cannot match the clean results of TIG or the efficiency of MIG, stick welding is a viable backup when circumstances are limited. For those who only occasionally weld aluminum, it’s a valuable skill for situations where functionality is the only requirement.

Conclusion

Stick welding aluminum is a possible but challenging method best reserved for a niche set of applications. It’s a functional solution for specific situations but is rarely the preferred choice when TIG or MIG alternatives are available.

Successful aluminum stick welding requires:

-

A DC stick welder set to DEEP (reverse polarity).

-

Specialized aluminum electrodes (e.g., E4043).

-

Amperage settings appropriate for the electrode (typically 80–130 amps for 1/8″ rods).

-

Thorough pre-weld and post-weld cleaning.

-

Realistic expectations regarding the final appearance.

Stick welding aluminum is a compromise solution—not ideal, but capable of producing functional welds when circumstances demand flexibility over perfection.

Stick Welding Aluminum – FAQ

Can you really weld aluminum with a stick welder?

Yes, aluminum can be welded with a stick welder, but it demands specialized aluminum electrodes (typically E4043) and a DC stick welder set to electrode positive (DEEP) polarity. The results won’t match the clean precision of TIG or MIG welding.

What thickness of aluminum can be stick welded?

Stick welding is only recommended for aluminum that’s 1/8″ (3.2mm) thick or greater. Attempting to stick weld thinner aluminum typically results in burn-through and excessive warping.

What amperage should I use for stick welding aluminum?

For common 1/8″ E4043 electrodes, use between 80–130 amps, depending on your aluminum’s exact thickness. Start at the lower end of the range and adjust as needed for proper penetration without burn-through.

Do I need AC or DC for stick welding aluminum?

You need DC (direct current) set to electrode positive (DEEP or reverse polarity). AC simply won’t work effectively with aluminum stick electrodes.

Why does my aluminum stick electrode keep sticking to the workpiece?

This is common with aluminum electrodes. Maintain a slightly longer arc length (1/8″ to 3/16″) than you would with steel, and ensure your amperage is sufficiently high for the electrode size you’re using.

How do I clean aluminum before stick welding?

Use a dedicated stainless steel brush (never used on steel) to remove the oxide layer, and clean with acetone or another aluminum-appropriate solvent to remove oils and contaminants. Clean immediately before welding—the oxide layer reforms quickly.

Is preheating necessary when stick welding aluminum?

Preheating to 200-300°F can be beneficial, especially for thicker sections, as it helps the electrode wet out better and improves penetration. However, it’s not always necessary for basic repairs.

Why does my stick-welded aluminum look so rough compared to TIG welds?

Stick welding aluminum inherently produces rougher welds with more spatter and slag inclusions. The flux coating on aluminum electrodes is particularly stubborn to remove completely, contributing to the less refined appearance.