Understanding Pulse MIG Welding Settings

Pulse MIG welding is an advanced evolution of the traditional MIG process, delivering exceptional control through its sophisticated cycling between high peak current and low background current. This rhythmic pulsing action creates precise heat management opportunities and offers significant benefits for weld quality—particularly when working with thin or sensitive materials that demand finesse.

Understanding how these settings work together is essential for achieving optimal results. Peak amperage delivers the necessary penetration and fusion power. Meanwhile, background amperage maintains arc stability while allowing the weld pool to cool strategically.

Key Parameters in Pulse MIG Welding

Mastering pulse MIG welding demands proficiency across several critical parameters:

-

Current Settings: Set both peak and background current. Peak current (typically 120-180A) provides penetration, while background current (30-50A) maintains the arc with minimal heat.

-

Pulse Frequency: Measured in Hertz (Hz), this controls pulses per second (typically 60-120 Hz). Higher frequencies create a more stable arc but increase heat.

-

Pulse Width (or Balance): Controls the proportion of time spent at peak current, directly affecting heat input and weld characteristics.

-

Wire Feed Speed (WFS): Measured in inches per minute (IPM), this determines how quickly filler wire is fed into the weld and must be balanced with current settings.

-

Up slope & Down slope: These settings control the gradual increase of current at the start of the weld (up slope) and the decrease at the end (down slope), preventing defects like crater cracking.

-

Contact Tip Diameter: The tip’s size must match the wire diameter to ensure consistent current transfer and arc stability.

Mastering these parameters allows welders to achieve the ideal balance between penetration, heat input, and weld quality across diverse materials and thicknesses. This produces Consistent, professional-grade welds that meet the most demanding specifications.

Creating a Pulse MIG Welding Settings Chart

A pulse MIG welding settings chart is a valuable reference tool that significantly improves both efficiency and quality. By providing optimal settings tailored to your specific project, it eliminates costly guesswork and reduces trial-and-error time.

When crafting your pulse MIG welding settings chart, organize it around the three most critical factors influencing welding parameters: material type, material thickness, and wire size. This approach helps you quickly identify the precise settings needed for any combination of these variables—saving valuable time in production environments.

For each material/thickness/wire combination, your chart should include recommended values for:

• Peak current (amperage)

• Background current (amperage)

• Pulse frequency (Hz)

• Wire feed speed (IPM)

• Voltage settings

• Recommended shielding gas mixture

• Travel speed guidelines

-

Use visual aids: Employ color coding or clear organization to make the chart easy to read.

-

Ensure durability: Laminate the chart to protect it from spatter and grime in a shop environment.

-

Create a digital version: Use a spreadsheet for easy access on a smartphone or tablet.

While charts provide excellent starting points, always fine-tune settings on scrap material first. This accounts for your specific equipment characteristics and environmental conditions before committing to production welding.

Example Settings for Different Materials

Below are proven starting points for pulse MIG welding settings across common materials. Remember: always test these settings on scrap material before beginning production welding, as equipment variations and environmental factors may necessitate adjustments.

Carbon Steel (1/8 inch thickness) :

• Peak Current: 150-180 Amps

• Background Current: 30-50 Amps

• Pulse Frequency: 60-120 Hz

• Wire Feed Speed: 200-300 IPM

• Shielding Gas: 75-95% Argon / 5-25% CO₂

• Wire Size: 0.035-0.045 inch

Aluminum (1/8 inch thickness) :

• Peak Current: 120-150 Amps

• Background Current: 30-50 Amps

• Pulse Frequency: 60-100 Hz

• Wire Feed Speed: 250-350 IPM

• Shielding Gas: 100% Argon

• Wire Size: 0.035-0.045 inch

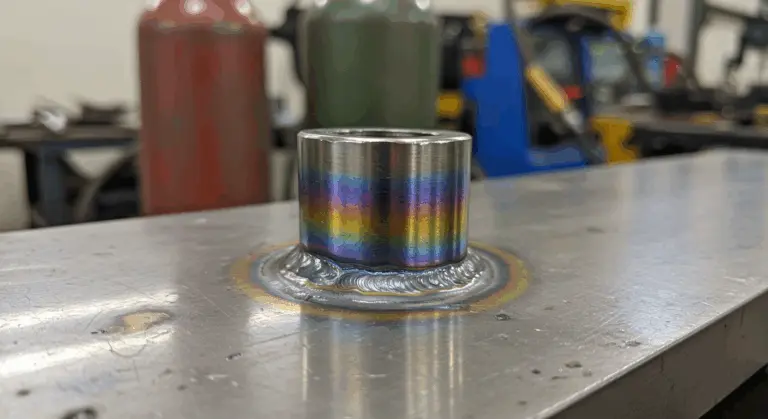

Stainless Steel (1/8 inch thickness) :

• Peak Current: 140-170 Amps

• Background Current: 30-50 Amps

• Pulse Frequency: 60-120 Hz

• Wire Feed Speed: 180-250 IPM

• Shielding Gas: 98% Argon / 2% CO₂ or trismic

• Wire Size: 0.035 inch

Thinner Materials (1/16 inch or less): For all materials at thinner gauges, reduce peak current by approximately 25-30% from the values listed above while maintaining similar background current levels. This approach provides adequate fusion while preventing burn-through—a common challenge with delicate materials.Thicker Materials (1/4 inch or greater): For thicker sections, increase peak current by 20-40% depending on thickness while maintaining background current at similar levels. Consider reducing pulse frequency slightly to allow more heat input per pulse—essential for achieving proper penetration in heavy sections.

Travel speed significantly impacts weld quality and requires careful consideration. Faster travel demands higher current for proper fusion. Conversely, slower travel may need reduced current to prevent excessive heat buildup and distortion.

Common Issues and Solutions in Pulse MIG Welding

Even with carefully optimized settings, pulse MIG welding can present challenges that require systematic troubleshooting. Understanding common issues and their proven solutions helps welders quickly identify and resolve problems—keeping productivity and weld quality high.

-

Porosity: Small holes in the weld bead caused by gas contamination.

-

Solution: Ensure proper gas flow (20-30 CFH), clean the base material, check for gas leaks, and shield the weld area from drafts.

-

Lack of Fusion: The weld metal fails to bond with the base material, creating a weak joint.

-

Solution: Increase peak current, reduce travel speed, or adjust the torch angle for better joint access.

-

Burn-through: Excessive heat creates holes in the base material, especially on thin sections.

-

Solution: Reduce peak current, increase travel speed, or adjust pulse frequency to lower overall heat input.

-

Inconsistent Bead Appearance: Variations in weld bead width, height, or pattern.

-

Solution: Maintain a steady travel speed, ensure consistent torch-to-work distance, and check for issues with the wire feed mechanism.

-

Excessive Spatter: Droplets of molten metal that scatter from the weld.

-

Solution: Fine-tune pulse parameters, adjust wire feed speed to match current, and verify proper shielding gas coverage.

Impact of Shielding Gas on Weld Quality

Shielding gas selection and delivery are crucial factors in pulse MIG welding quality, often making the difference between excellent and poor results. While the primary function involves protecting the molten weld pool from atmospheric contamination, its influence extends far beyond simple protection.

Different shielding gases create different arc characteristics and significantly affect weld penetration profiles. For aluminum, pure argon (100%) provides excellent cleaning action and very stable arc characteristics.

Gas flow rate is critical for success. Insufficient flow causes porosity, while excessive flow—a surprisingly common mistake—creates turbulence that pulls in atmospheric contaminants. For most applications, 20-30 cubic feet per hour (CFH) provides optimal coverage without waste.

-

Drafts: Wind from fans, open doors, or outdoor work can blow away shielding gas, requiring the use of windshields.

-

Humidity: High humidity can introduce hydrogen into the weld, potentially causing cracks in sensitive materials.

-

Contaminants: A dusty or dirty workspace can introduce particulates into the weld, causing inclusions and porosity.

Gas delivery system maintenance is often overlooked but essential. Check regularly for leaks in hoses, fittings, and regulators that waste expensive gas and compromise coverage quality.

For optimal results, consistently manage your shielding gas system:

Advantages of Using Pulse MIG Welding

Pulse MIG welding provides significant advantages that make it increasingly popular across diverse industries—from automotive manufacturing to aerospace applications. These benefits help welders decide when this technique provides optimal value compared to conventional methods.

-

Precise Heat Control: The pulsing cycle results in 15-30% lower overall heat input compared to conventional MIG, reducing distortion and minimizing the heat-affected zone.

-

Spatter Reduction: Produces up to 90% less spatter, drastically cutting down on post-weld cleanup time and material waste.

-

All-Position Capability: The controlled metal transfer allows for easier overhead and vertical welding with less risk of dripping, increasing flexibility.

-

Higher Productivity: Achieves 10-15% higher deposition rates than conventional MIG at similar heat levels, enabling faster weld completion.

-

Superior Aesthetics: Creates a clean, uniform “stacked dimes” appearance that often requires no post-weld grinding.

-

Material Versatility: Excels on thin or challenging materials like aluminum and stainless steel, preventing burn-through while ensuring full penetration.

Comparing Pulse MIG with Traditional MIG Welding

When evaluating welding processes for specific applications, understanding the key differences between pulse MIG and traditional MIG welding supports better decision-making. Consider project requirements, material considerations, and quality expectations when making your choice.

| Feature | Pulse MIG | Traditional MIG |

|—|—|—|

| Metal Transfer | Controlled, one-drop-per-pulse transfer for all positions. | Short-circuit or spray transfer, position-dependent. |

| Arc Stability | Highly stable arc with ~60-70% less variation. | Less stable, prone to fluctuations. |

| Equipment Cost | Higher initial investment (30-50% more). | Lower cost, simpler equipment. |

| Material Thickness | Excellent for thin materials (down to 24 gauge), good for moderate thickness. | Best for thicker materials (3/16″+), struggles with thin sections. |

| Operator Skill | Requires more training to optimize advanced parameters. | Simpler to learn for basic operation. |

| Energy Efficiency | More efficient, consuming 10-20% less power for equivalent welds. | Higher energy consumption and heat input. |

For most applications requiring high-quality welds on thin or sensitive materials, pulse MIG provides better results despite higher equipment costs. However, for thicker materials where heat input is less critical—or in environments where equipment simplicity and cost are primary concerns—traditional MIG often remains the practical choice.