What is a Weld Puddle?

A weld puddle—also known as a weld pool—represents the molten metal that forms during the welding process. In this molten state, base metals fuse together, sometimes incorporating additional filler material, before cooling and solidifying into a permanent bond.

Several critical factors shape the characteristics of any weld puddle:

-

Welding Process: The method used (e.g., TIG, MIG, stick) dictates puddle behavior.

-

Torch/Electrode Angle: The angle of approach influences heat distribution and visibility.

-

Heat Input: The amount of amperage applied controls the melting rate.

-

Travel Speed: The speed of movement along the joint affects puddle size and penetration.

Depending on the specific application, a weld puddle’s composition may include:

-

Parent Metal Only: The puddle is formed solely from the melted base materials.

-

Parent and Filler Metal: A combination of the base material and an added wire or rod.

-

Primarily Filler Metal: Used in surfacing operations to build up a surface.

Throughout the welding process, the puddle requires protection from atmospheric contamination. This shielding—typically provided by inert gases like argon—prevents oxidation until the metal fully solidifies.

Importance of Weld Puddle Control

Mastering weld puddle control is essential for producing high-quality welds. The puddle’s leading edge demands particular attention, as this critical zone initiates the fusion between base and filler metals.

This control proves particularly important in precision welding methods like TIG (Tungsten Inert Gas). When welders can recognize and respond to puddle behavior in real-time, they prevent defects before they occur—saving valuable time, materials, and eliminating costly rework.

Maintaining the correct puddle size is essential. An oversized puddle—caused by excessive heat—can trigger several problems:

When welders achieve proper puddle control, they gain precise command over heat input and travel speed. The result? Welds that exhibit optimal penetration, superior appearance, and robust structural integrity—the mark of skilled welding.

Techniques for Effective Weld Puddle Control

Achieving effective puddle control combines proper technique, optimal equipment settings, and focused practice—all tailored to your specific welding process.

Heat management is fundamental to puddle control. Begin with setting the correct amperage based on your material’s thickness and type. Thinner materials demand lower amperage to prevent burn-through while ensuring adequate fusion. Thicker sections require higher amperage for proper penetration.

Travel speed—your movement rate along the joint—directly governs puddle size and penetration depth. Move too slowly? The puddle grows excessively large, potentially sagging or burning through. Rush too quickly? You’ll achieve inadequate fusion and create weak joints.

Torch angle and standoff distance significantly affect puddle behavior. Generally, a 15-20 degree pushes angle in your travel direction provides optimal visibility and control across most processes.

When working with filler metal processes, develop a steady rhythm of dipping the rod into the puddle’s leading edge. This technique creates consistent bead appearance and penetration. In TIG welding, this approach—sometimes called “walking the cup”—enables precise puddle manipulation while maintaining forward progress.

Visual Indicators of Weld Puddle Quality

Learning to interpret the puddle’s visual signals ensures quality control. A well-formed puddle typically appears as a sloping oval with a distinctly raised leading edge. Steeper sides? That often signals deeper penetration.

Color also indicates weld quality. In TIG welding, a healthy puddle should gleam bright and silvery—like liquid mercury. Spot any discoloration? Browns, blues, or blacks may signal contamination from inadequate gas shielding or surface impurities.

The puddle’s dynamics—its flow patterns and behavior—reveal crucial information about subsurface conditions to experienced welders. A well-controlled puddle exhibits smooth, even flow with minimal turbulence.

Another critical visual cue involves observing how weld metal and slag separate during cooling. In slag-producing processes like stick welding, you should see clear distinction between solidifying weld metal and slag formation. The slag should float cleanly to the surface rather than becoming trapped within the weld.

The “keyhole” or “Devil’s eye” phenomenon—a small depression at the puddle’s leading edge—is especially important in TIG welding as it indicates proper penetration. This keyhole should remain consistently sized throughout the weld. Too large suggests excessive heat; disappearing entirely indicates insufficient penetration.

Common Issues with Weld Puddles

Porosity—those troublesome small holes or bubbles in completed welds—commonly results from contamination, inadequate gas shielding, or moisture. Clean materials and proper gas flow help prevent this defect.

Struggling to establish the initial puddle? This frustrating issue typically stems from insufficient voltage or inadequate heat at weld startup. Try increasing output voltage or adjusting start current settings on your machine.

Poor puddle fluidity—where molten metal appears sluggish or flows poorly—usually indicates insufficient heat or improper technique. When filler material fails to melt properly into the puddle, it creates weak spots in the finished weld.

Crater formation at weld pass endings presents another common challenge. These depressions occur when the arc terminates abruptly, causing the puddle to collapse inward during solidification.

Lack of fusion—where weld metal fails to bond properly with base metal—often stems from poor puddle control. This serious defect creates weak points that may fail under stress.

Misalignment issues during welding can cause unpredictable puddle behavior. Proper fit-up before welding, appropriate fixturing, and consistent technique throughout the weld pass help minimize alignment-related puddle problems.

Tools and Equipment for Weld Puddle Management

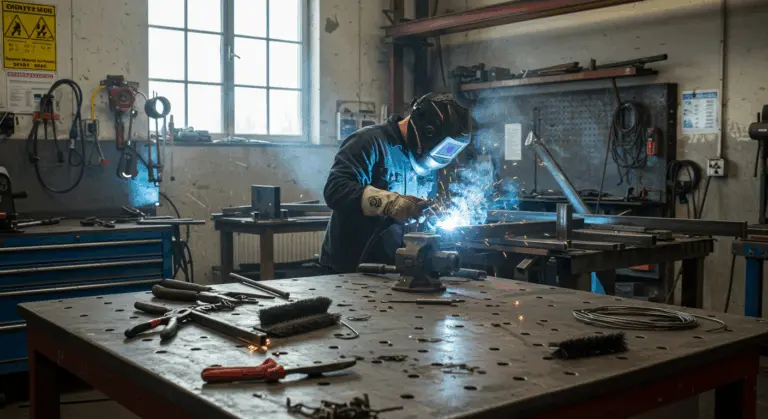

Effective weld puddle management starts with selecting appropriate tools and equipment for your specific application. A quality auto-darkening welding helmet is crucial for puddle control.

Proper lighting conditions in your workspace greatly affects puddle monitoring ability. Professional welding stations often incorporate adjustable task lighting that illuminates work areas without creating glare or shadows that might obscure puddle details.

| Process | Name | Puddle Characteristics | Control Demands |

|—|—|—|—|

| SAW | Shielded Metal Arc Welding (Stick) | Partially obscured by slag | Requires reading slag and puddle together |

| GTA | Gas Tungsten Arc Welding (TIG) | Clean and highly visible | Demands high precision and manual control |

| GMA | Gas Metal Arc Welding (MIG) | Fast-forming and fluid | Requires quick reaction times |

For precision TIG welding, specialized accessories enhance control:

-

Torch Accessories: Cup walking kits, flexible necks, and various cup sizes improve access and visibility.

-

Amperage Controls: Foot pedals or fingertip controls allow for real-time heat adjustments.

Advanced welding power sources with pulsing capabilities offer another dimension of puddle control. By alternating between high and low current settings many times per second, these machines create more manageable puddles—especially beneficial on thinner materials or during out-of-position welding.

Gas delivery systems with precise flow control ensure consistent puddle shielding throughout the welding process. Some setups include gas lenses or specialized distribution accessories that provide more uniform coverage—particularly beneficial when working in drafty conditions that might disturb the shielding gas envelope.

Training and Skills for Mastering Weld Puddles

Developing weld puddle control expertise requires focused practice and systematic skill building. Beginners should start with basic exercises on scrap material, allowing experimentation without production pressure.

Foundational preparation for effective puddle control encompasses:

-

Ensuring pieces have a square, straight, and proper fit-up.

-

Debarring all edges to remove contaminants.

-

Thoroughly cleaning the weld area.

-

Back-purging with argon for critical materials like stainless steel or aluminum to create an oxygen-free environment.

Experienced welders develop intuitive puddle reading abilities. For instance, maintaining a consistent “keyhole” at the puddle’s leading edge consistently shows proper penetration—an important skill marker.

Developing muscle memory for consistent travel speed is important. Some welders practice to a rhythm—occasionally using a metronome—to internalize the correct pace and prevent puddle size variations.

Advanced puddle control encompasses techniques for managing weld start and end points—often the most problematic areas. Overlapping start and end points creates stronger welds by ensuring complete fusion throughout the joint.

Formal training through welding schools, apprenticeships, or manufacturer-sponsored programs helps speed up learning. These structured environments provide progressive exercises designed to systematically build puddle control skills.

Skill develops through continuous feedback loops: observing the puddle and immediately adjusting heat, angle, speed, and filler addition to maintain optimal conditions.