Understanding Dual Shield Welding – Definition and Overview

Dual shield welding is formerly known as flux-cored arc welding (FLAW), an arc welding process that emerged in the 1950s as an alternative to traditional manual metal arc (MMA) welding. This technique combines the efficiency of continuous wire feeding with constant-voltage power delivery, utilizing equipment architecturally similar to metal active gas (MAG) systems.

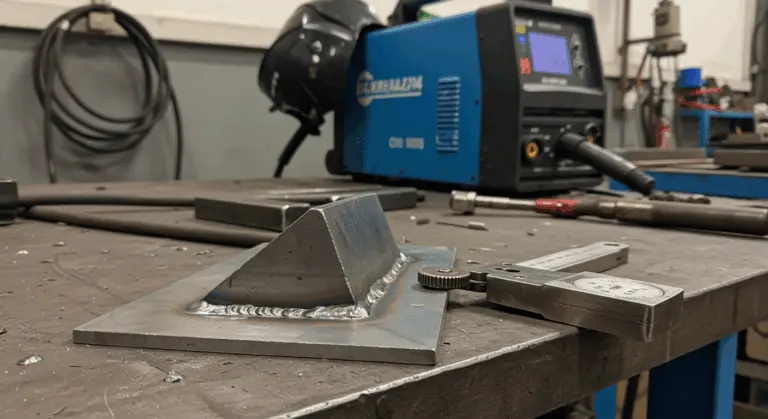

What sets dual shield welding apart is its dual-layer protection system for the weld pool. By combining internal flux within the wire electrode with external shielding gas, this method creates an exceptionally controlled welding environment—yielding cleaner, stronger welds that are essential in mission-critical structural applications.

The key difference between dual-shielded and self-shielding FLAW is important to understand. Dual-shielded wire demands an external gas source but rewards you with aesthetically superior welds perfect for indoor applications.

The Dual Shield Welding Process – How It Works

The process employs a continuously fed, flux-cored wire electrode while an external shielding gas—typically CO₂ or an Argon/CO₂ blend—flows through the welding gun, supplementing the protection already provided by the wire’s internal flux.

When the arc ignites, several things occur simultaneously. The flux inside the wire melts and releases protective gases, forming the first defensive barrier against atmospheric contamination.

The flux components perform several functions beyond protection—they introduce vital alloying elements to the weld, shape the bead profile, and can significantly enhance the finished weld’s mechanical properties.

Benefits of Dual Shield Welding – Why Choose This Method?

Dual shield welding delivers several compelling advantages, starting with superior weld quality. The combination of internal flux and external shielding gas creates welds that are cleaner, stronger, and more defect-resistant than those produced by many competing processes.

The aesthetic advantages are equally impressive. This process consistently produces smooth, well-formed beads with minimal spatter—creating welds that don’t just perform exceptionally but look genuinely professional.

Higher productivity is another reason for choosing dual shield welding. The process achieves higher deposition rates than stick welding (SAW) and even outperforms some other wire-fed processes.

Applications of Dual Shield Welding – Where Is It Used?

Dual shield welding is widely used in industries where weld quality and structural integrity are critical. In construction—particularly for towering high-rises and massive infrastructure projects—this process is the go-to choice for critical structural connections.

Shipbuilding is another key application for dual shield welding. Naval vessels and commercial ships must withstand constant saltwater exposure and high structural stresses.

Heavy machinery manufacturing relies heavily on dual shield welding’s capabilities. Equipment destined for mining, agriculture, and construction must survive punishing operational stresses and hostile environments.

Beyond these major industries, dual shield welding is also used in:

-

Railroad car manufacturing

-

Pressure vessel fabrication

-

Bridge construction

-

Automotive frame production

The process is particularly valuable for fabricating high-integrity structures from medium to thick materials in controlled environments.

Common Challenges in Dual Shield Welding – Issues to Watch For

Despite its numerous advantages, dual shield welding presents several challenges that welders must address to achieve optimal results. Weld integrity verification stands as perhaps the most significant concern, particularly in complex structures where visual inspection alone is often insufficient.

Porosity is another common problem in dual shield welding. This defect occurs when gas becomes trapped within the solidifying weld metal, creating small voids that weaken the joint.

Lack of fusion defects—where weld metal fails to properly bond with base material—can also plague dual shield operations. This typically results from insufficient heat input, improper travel speed, or incorrect torch positioning.

Common technical errors that degrade weld quality include:

-

Excessive Arc Length: A long arc compromises shielding gas coverage.

-

Improper Torch Angle: An incorrect angle can lead to uneven penetration.

-

Loss of Shielding: Failing to keep the filler material within the gas envelope during and after welding.

To minimize these challenges, successful dual shield welding operations emphasize proper equipment maintenance, thorough material preparation, consistent technique, and appropriate post-weld treatment. Additionally, implementing comprehensive quality control procedures, including both visual inspection and non-destructive testing methods, helps ensure that any defects are identified and addressed before the welded structure enters service.

Setting Up for Dual Shield Welding – Equipment and Techniques

Proper setup is the foundation for high-quality results, beginning with a constant-voltage power source capable of delivering the steady electrical output this process demands. This must be paired with a wire feeder mechanism that reliably delivers flux-cored wire at consistent speeds—typically ranging from 100 to 300 inches per minute depending on application requirements.

The welding gun for dual shield FLAW must accommodate both wire feed and shielding gas flow seamlessly. Most professional setups employ water-cooled guns for high-amperage applications, preventing overheating during extended use.

Wire selection represents another critical aspect of the setup process. Dual shield flux-cored wires come in various diameters and compositions, each meticulously designed for specific applications and material types.

Parameter configuration involves setting wire feed speed based on manufacturer recommendations and fine-tuning voltage (typically 18-35V) to achieve desired arc characteristics. Proper technique demands maintaining correct work angle (5-15 degrees), travel angle (10-20 degrees), and consistent electrode extension (stick-out) of approximately 3/4 to 1 inch.

For best results, ensure your work area is free from contaminants like oil, rust, or moisture—any of which can seriously compromise weld quality. Additionally, proper ground connection is essential for stable arc performance.