What Is Arc Welding?

Arc welding is a fusion process that uses an electric arc between an electrode and the base material to join metals. This arc generates intense heat—approximately 6,500°F (3,600°C)—which melts the metals at the joint. As they cool and solidify, a strong metallurgical bond forms.

A power supply creates the electric arc that travels from the electrode to the workpiece, utilizing either direct (DC) or alternating (AC) current. The electrode can be consumable, melting into the weld, or non-consumable. Protective measures like shielding gas or slag prevent atmospheric contamination that could compromise the weld’s integrity.

As one of the most versatile and widely used welding methods, arc welding is essential for joining various metals and thicknesses across construction, manufacturing, and repair applications. The process adapts to both manual and automated operations, offering excellent flexibility for diverse project requirements.

Types of Arc Welding Techniques

Arc welding includes many different of techniques. The primary processes, which form the backbone of industrial welding, include:

-

Shielded Metal Arc Welding (SAW) or stick welding

-

Gas Metal Arc Welding (GMA) or MIG/MAG welding

-

Flux-Cored Arc Welding (FLAW)

-

Gas Tungsten Arc Welding (GTA) or TIG welding

-

Submerged Arc Welding (SAW)

Specialized arc welding processes have also been developed for specific applications:

-

Plasma Arc Welding (PAW)

-

Carbon Arc Welding

-

Atomic Hydrogen Welding

-

Electro slag Welding

-

Stud Welding, including Drawn Arc (DA) and Capacitor Discharge (CD) variants.

Each technique brings unique advantages in terms of quality, speed, cost-effectiveness, and material compatibility.

Selecting the optimal arc welding technique depends on several important factors: base material composition and thickness, joint design, production requirements, and environmental conditions. Understanding each method’s strengths and limitations is important for achieving superior results.

Shielded Metal Arc Welding (SAW)

Shielded Metal Arc Welding (SAW), commonly known as stick welding, is a highly versatile process that employs a flux-coated electrode rod serving dual purposes as both filler material and arc conductor. As the arc melts the electrode and base metal, the flux coating burns away, creating a protective gas shield and slag that prevents atmospheric contamination of the weld pool.

SAW offers several key advantages:

-

Portability: It requires minimal equipment, making it ideal for field work.

-

Durability: The process functions effectively outdoors and in windy conditions.

-

Versatility: With the right electrode, it can weld most metals, making it essential for construction, mining, and heavy manufacturing.

However, SAW presents certain limitations. Slower travel speeds and reduced efficiency from frequent electrode changes can impact productivity. The process also demands considerable operator skill to master effectively. However, its basic design and exceptional portability make it indispensable for maintenance and repair work, particularly in remote locations where other methods are not feasible.

Gas Metal Arc Welding (GMA)

Gas Metal Arc Welding (GMA), widely known as MIG (Metal Inert Gas) welding, is a semi-automatic or fully automatic process that employs a continuously fed wire electrode serving dual roles as electrical conductor and filler metal. A protective shielding gas—either inert or semi-inert—flows from the welding gun to safeguard the weld pool from atmospheric contamination.

GMA operates through three primary metal transfer methods: Short Circuit Transfer for thinner materials and out-of-position welding, Spray Transfer for achieving deeper penetration on thicker materials, and Pulse Transfer, which combines aspects of both while minimizing heat input. The process demands a constant voltage, direct-current power source and excels particularly with plate and large-bore pipe applications.

MIG welding’s widespread popularity comes from several key benefits: exceptional welding speeds, relatively straightforward learning curve, clean welds with minimal slag, and excellent versatility across different metals. It dominates industrial processes, particularly in automotive manufacturing. While producing smooth welds requiring minimal cleanup, it remains sensitive to wind conditions, making it best suited for indoor applications.

Flux-Cored Arc Welding (FLAW)

Flux-Cored Arc Welding (FLAW) was developed in the 1950s as a strong alternative to SAW. This semi-automatic process utilizes equipment similar to GMA but features a distinctive tubular wire electrode filled with flux, effectively combining the continuous feed advantage of MIG welding with the flux protection characteristic of stick welding.

FLAW operates through two primary variants: Self-shielded (FLAWS), where the flux core generates its own protective atmosphere—ideal for outdoor and windy conditions—and Gas-shielded (FLAG), which employs external shielding gas for superior weld quality but requires more controlled environments.

With its high deposition rate and deep penetration capabilities, FLAW excels when working with thicker materials. It has become indispensable in heavy industries such as bridge construction, equipment repair, and structural steel fabrication, where its high efficiency and strength are essential.

Gas Tungsten Arc Welding (GTA)

Gas Tungsten Arc Welding (GTA), commonly called TIG (Tungsten Inert Gas) welding, is known for its exceptional precision and quality. It employs a non-consumable tungsten electrode paired with an inert shielding gas—typically argon or helium—to protect the weld. GTA is unique because Unlike other methods, it can be performed with or without filler material, offering great flexibility.

TIG welding produces exceptionally clean, precise, and high-quality welds while granting the welder superior control over the entire process. This makes it ideal for thin materials, critical applications, and welding reactive or exotic metals, including stainless steel, aluminum and magnesium, titanium, and nickel and copper alloys.

Though it produces the highest quality welds, GTA presents complexity that demands significant skill development. Despite slower deposition rates compared to GMA or FLAW, it remains indispensable in industries where superior quality is non-negotiable—aerospace, nuclear, and high-performance fabrication. The resulting joints are exceptionally strong and often require no cleanup whatsoever.

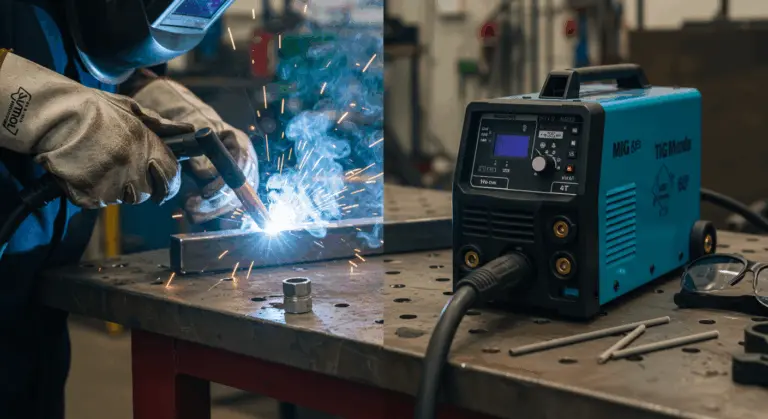

Arc Welding Equipment and Safety Gear

Arc welding demands specialized equipment and comprehensive safety gear. The fundamental equipment varies by process but typically includes a power source (AC or DC), electrode holders or welding guns, work clamps and cables, and gas cylinders with regulators for gas-shielded processes. Additional tools like wire brushes and grinders prove essential for preparation and cleaning tasks.

Safety remains paramount due to multiple serious hazards, necessitating comprehensive personal protective equipment (PPE). Key risks include intense ultraviolet (UV) and infrared (IR) radiation, extreme heat and molten metal splatter, electrical shock, and harmful fumes and gases. Proper protection is absolutely essential to prevent serious injuries such as burns, eye damage, and respiratory illness.

Quality equipment from reputable manufacturers like ESA, Lincoln Electric, and Miller ensures operational reliability while enhancing safety standards. Investing in proper equipment and PPE is a basic requirement of professional welding that directly impacts both work quality and welder health—it’s not optional.

Essential Tools for Arc Welding

While configurations vary significantly, all arc welding setups center around a power supply. These can be transformer-based AC units, rectifier-based DC units, or modern inverter-based systems offering precise control over welding parameters. The choice between AC and DC power depends on the specific welding process and material requirements.

Electrodes represent another critical, process-specific component. SAW uses flux-coated consumable rods, GMA and FLAW employ continuously fed wire, while GTA utilizes non-consumable tungsten electrodes. Each type requires a specific holder or gun design. All setups also need electrode and work cables with clamps to complete the electrical circuit effectively.

Welders also require auxiliary tools for preparation, process management, and finishing work: cleaning tools like wire brushes and grinders, measuring instruments for proper joint fit-up, positioning tools including clamps and fixtures, slag removal tools such as chipping hammers, and gas delivery systems comprising cylinders, regulators, and hoses for gas-shielded processes.

Safety Gear for Welders

Proper safety gear is essential. The most important piece is the welding helmet, which shields the face and eyes from dangerous UV and IR radiation. Modern auto-darkening helmets (shade #10-13) offer superior protection and visibility. Safety glasses with side shields should always be worn underneath the helmet as an additional safeguard.

Fire-resistant (FR) clothing forms the next critical layer of protection. This includes heavy-duty leather gloves extending over the wrists, FR jackets or coveralls paired with leather aprons to shield against sparks, cuffless pants that cover the tops of boots, and high-top leather safety boots with steel toes for comprehensive foot protection.

Respiratory protection is important for avoiding harmful fumes and gases. Required equipment depends on the material and environment, ranging from simple particulate masks to sophisticated Powered Air-Purifying Respirators (Pairs). Additional protection includes FR head coverings or bandanas for overhead sparks and hearing protection—earmuffs or plugs—for noisy environments.

Applications of Arc Welding

Because of its versatility and reliability, arc welding serves as a cornerstone technology across numerous industries. In construction, it’s fundamental for fabricating structural steel for buildings and bridges. The shipbuilding industry relies heavily on processes like SAW and FLAW to construct vessel hulls and superstructures capable of withstanding harsh marine environments.

The automotive industry employs arc welding extensively for vehicle frames, chassis, and exhaust systems to ensure structural integrity. Heavy equipment manufacturing depends on it to join thick steel plates for construction and mining machinery. Even the aerospace industry utilizes arc welding for ground support equipment applications.

Beyond these major sectors, arc welding is important in countless other applications: Oil & Gas for pipeline construction and pressure vessel fabrication, Power Generation for building power plants and renewable energy infrastructure like wind turbines, General Manufacturing for fabricating machinery and industrial equipment, and even Art & Architecture for creating sculptures and custom metalwork. This widespread adoption shows how important this technology is in industry.

Conclusion: The Future of Arc Welding

The future of arc welding is being shaped by technological advancements that enhance efficiency, quality, and accessibility. Automation and robotics are at the forefront, with sophisticated welding robots handling increasingly complex tasks. When augmented by AI and machine learning, these systems adapt to variations in real-time, ensuring consistent quality while addressing the industry’s growing skills gap.

Digitalization is transforming the field through advanced data analytics and connectivity. Modern power sources collect comprehensive process data for real-time quality monitoring and predictive maintenance. Virtual and augmented reality (VR/AR) are revolutionizing welder training as well, allowing apprentices to practice safely while accelerating skill development.

Hybrid processes, such as laser-arc welding, are becoming more popular by combining the advantages of multiple technologies. The industry is simultaneously moving toward sustainability with more energy-efficient equipment, reduced waste, and improved fume extraction systems. As these innovations come together, arc welding will continue evolving—becoming safer, more efficient, and ensuring its vital role for a new generation of fabricators.