Understanding Welding – What is Welding?

Welding is a fabrication process that permanently joins materials—typically metals or thermoplastics—through the application of heat, pressure, or both. What sets welding apart from mechanical fastening? The weld itself becomes an integral component of the structure, creating joints that can match or even exceed the strength of the original base material. This ancient craft has transformed dramatically from primitive forge welding into today’s sophisticated processes that form the backbone of modern industry.

Why Good Welding Matters – Importance of Weld Quality

High-quality welds form the foundation of safety and structural integrity—a single weld failure can cause catastrophic consequences in critical applications like bridges, pressure vessels, or aircraft components. Distinguishing good welds from poor ones isn’t just valuable—it’s essential.

Weld quality directly dictates a structure’s performance and longevity. Several factors influence this quality: selecting compatible materials and the welder’s skill in handling the complexities of different welding positions.

Visual inspection provides the first line of quality control—a clean, uniform appearance typically signals sound technique. However, appearances can be misleading. Internal strength is equally important and often requires additional testing to verify structural integrity.

Characteristics of a Good Weld – What to Look For

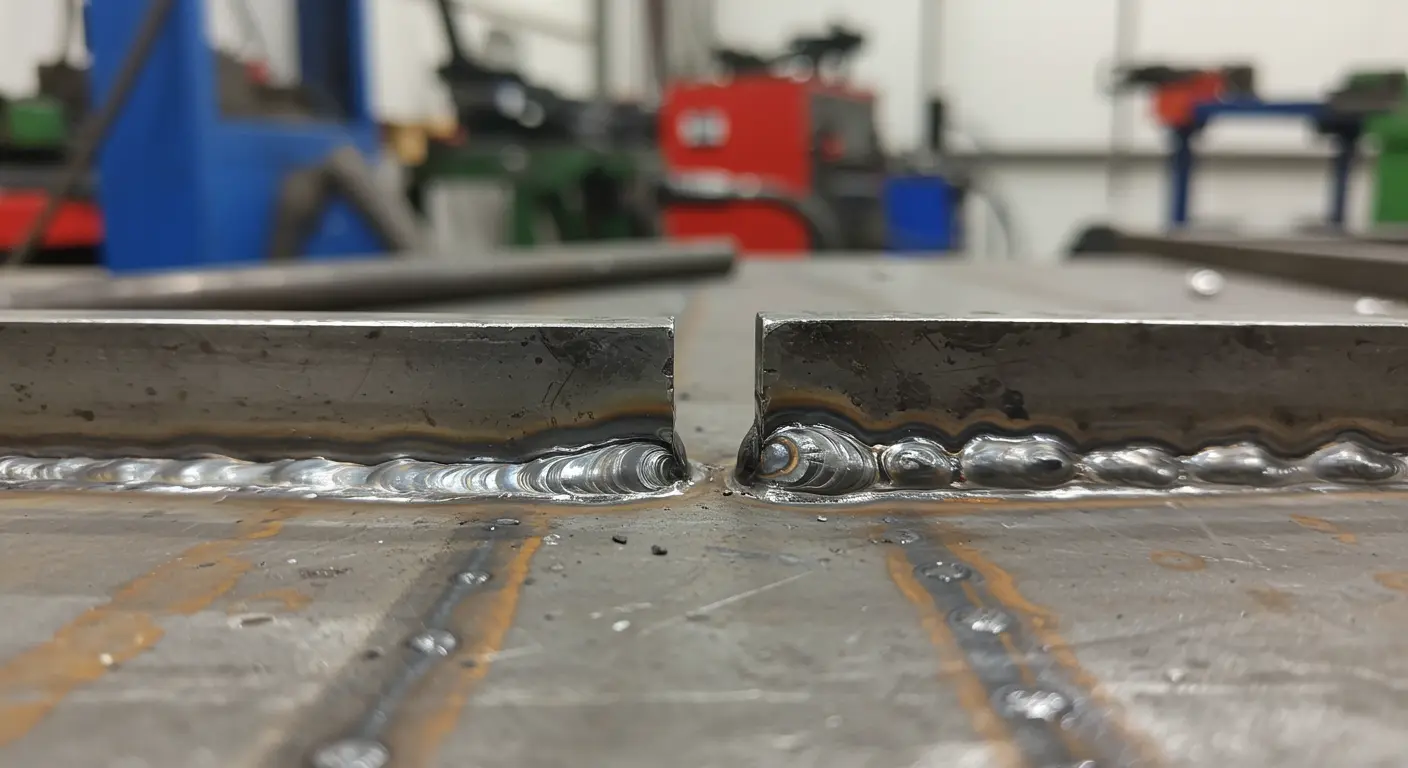

A good weld combines strength, durability, and clean appearance. The bead should maintain consistent dimensions with a smooth, even surface—clear evidence of steady, controlled technique. Quality welds are free from critical defects: no cracks, porosity (gas pockets), or undercutting. Minimal spatter further indicates professional execution. The final joint must achieve strength levels that match or surpass the base metals, preserving the structural integrity of the entire assembly.

Appearance of a Good Weld – Visual Indicators

Welding Technique and Skill – The Role of the Welder

A welder’s skill is fundamental to weld quality, blending technical knowledge with physical precision and unwavering hand control. Mastery requires extensive practice—only through repetition can welders consistently control their equipment and produce quality results.

Skilled welders must also navigate complex decisions: selecting the optimal process (MIG, TIG, or others), choosing appropriate consumables, and fine-tuning critical parameters like voltage and travel speed based on material characteristics and thickness. The ability to adapt these variables to changing conditions separates good welders from great ones.

Safety consciousness represents another cornerstone of expertise. Professional welders consistently use proper protective equipment and possess deep understanding of how to forge structurally sound joints that prevent catastrophic failures. These three elements—technical skill, physical control, and safety awareness—define the expert welder.

Identifying Bad Welding – Common Defects to Watch For

Recognizing poor welds is just as important as identifying good ones. Poor welds betray themselves through inconsistency: uneven surfaces, erratic bead patterns, and telltale defects like discoloration—often revealing improper heat management or inadequate shielding protection.

-

Cracks: Fissures that can propagate and cause catastrophic failure.

-

Porosity: Gas pockets or bubbles trapped within the weld, weakening the joint.

-

Lack of Fusion/Overlap: The weld metal fails to fuse with the base metal.

-

Burn-through: Excessive heat creates holes in the base metal.

-

Undercutting: A groove is melted into the base metal at the weld toe.

-

Spatter: Molten metal droplets scattered on the surrounding surface.

-

Improper Weld Profile: Includes underbilled welds (insufficient material) or excessive reinforcement (too much buildup).

-

Structural Issues: Includes distortion, mechanical damage, or misalignment of parts.

Wire welding processes like MIG can generate distinctive defects: pinholes, insufficient penetration, incomplete fusion between weld and base metal, and bead irregularities. These flaws don’t just affect appearance—they significantly reduce strength and reliability.

Common Welding Defects – What to Avoid

Cracks are among the most dangerous defects—they spread and can cause complete structural failure. Thermal stress typically causes these fissures, but proper edge preparation, preheating, and post-weld heat treatment can prevent their formation, particularly in thicker materials.

Porosity—gas bubbles trapped within the weld—seriously weakens joint strength. This defect typically stems from contamination, insufficient shielding gas coverage, or careless electrode handling. Lack of fusion presents another critical weakness: when weld metal fails to properly melt and integrate with base metal, it creates vulnerable points throughout the structure.

MIG welding presents its own characteristic defects: excessive spatter, convex and concave weld profiles (indicating improper wire feed or travel speeds), underbill conditions, and excessive reinforcement buildup. Burn-through occurs when too much heat creates holes in thin materials—damage that’s difficult to repair.

Preventing Common Welding Mistakes – Tips for Success

Preventing defects starts with careful preparation: remove all surface contaminants including oil, rust, and paint residues. Before striking an arc, verify that equipment functions correctly and welding parameters—amperage, voltage, travel speed—are precisely calibrated for the specific material and thickness requirements.

Good technique is the foundation of quality welding. Establish a stable body position that enables smooth, consistent hand movement along the joint path. Maintain correct work and travel angles while using clamps or positioning devices to ensure perfect alignment and minimize distortion. Novice welders should invest significant practice time on scrap materials to build both confidence and muscle memory.

Different materials require special attention. Stainless steel and specialized alloys require compatible, high-grade consumables paired with better shielding using inert gases like argon. TIG welding presents unique challenges: maintaining proper arc length, controlling torch angles, and keeping filler rods within the protective gas envelope during both welding and post-flow periods.

Good Weld vs Bad Weld – Key Differences Explained

Weld Quality Indicators – Assessing Strength and Durability

Assessing weld strength and durability requires examining several key quality indicators. Proper penetration and fusion are most important—welds must penetrate sufficiently into base metal to establish robust bonds, yet not so deeply that they compromise structural integrity. Complete fusion ensures weld metal thoroughly integrates with base material throughout the joint, eliminating potential failure points.

Weld profile analysis reveals important quality clues. An appropriate convex or flat profile (depending on application requirements) indicates proper technique and parameter selection. The weld toe—where weld metal meets base material—should transition smoothly without undercutting or excessive buildup. When accessible, the weld root should demonstrate complete penetration throughout its depth.

Heat-affected zone (HAZ) material properties significantly impact overall weld integrity. Excessive heat input can alter the metallurgical characteristics of base metal adjacent to the weld, potentially creating brittle regions prone to failure. Pre-heating, inter-pass temperature monitoring, and post-weld heat treatment help preserve desirable material properties throughout the welded assembly.

Weld Testing Methods – Ensuring Quality

Complete weld quality assurance requires systematic testing throughout the entire welding process. Quality assurance and quality control (QA/QC) procedures catch issues early, preventing defective output while ensuring final products meet all specifications. Testing methodologies span from straightforward visual inspection to sophisticated non-destructive testing (NDT) techniques that reveal internal flaws without compromising weld integrity.

-

Visual Testing (VT): The first line of defense, used to identify surface-level defects like cracks, porosity, and improper weld size. It is quick but cannot detect internal flaws.

-

Penetrant Testing (PT): Uses a dye to reveal surface-breaking defects that are not visible to the naked eye.

-

Magnetic Particle Testing (MT): Detects surface and near-surface flaws in ferromagnetic materials.

-

Ultrasonic Testing (UT): Employs sound waves to detect and characterize internal defects such as cracks and inclusions.

-

Radiographic Testing (RT): Uses X-rays or gamma rays to create an image of the weld’s internal structure, revealing hidden flaws.

Conclusion – Summary of Good vs Bad Welds

The difference between good and poor welds directly affects safety, reliability, and service longevity. Good welds create strong, uniform, defect-free joints that properly integrate with the base structure. Poor welds, conversely, become critical weak points destined for failure. Understanding these differences and using proper inspection methods is essential for ensuring welded structures perform safely and effectively throughout their intended operational life.

Frequently Asked Questions – Common Queries on Welding

What distinguishes a “good” weld from a “bad” one?

Good welds show uniform appearance, adequate penetration, complete fusion with base metal, and no defects like cracks or porosity. They create joints that match or exceed base material strength. Poor welds show inconsistency, visible defects, incomplete fusion, and heightened failure risk under stress.

How can I check if a weld is strong enough?

While visual inspection identifies many quality indicators, critical applications require non-destructive testing methods—ultrasonic or radiographic examination—to verify internal integrity. Quality welds demonstrate proper penetration, complete fusion, and no internal defects.

What causes most welding defects?

Most defects originate from inadequate preparation, incorrect parameter settings (amperage, voltage), insufficient gas shielding, poor technique execution, or equipment malfunctions. Proper setup and skilled execution can prevent the vast majority of these problems.

Which welding method delivers the strongest results?

Weld strength depends more on proper execution than the welding method used. While TIG welding often produces better quality for critical applications, MIG, stick, and other processes can achieve equally strong results when executed skillfully with appropriate parameters for specific materials and joint configurations.

How do I select a qualified welder?