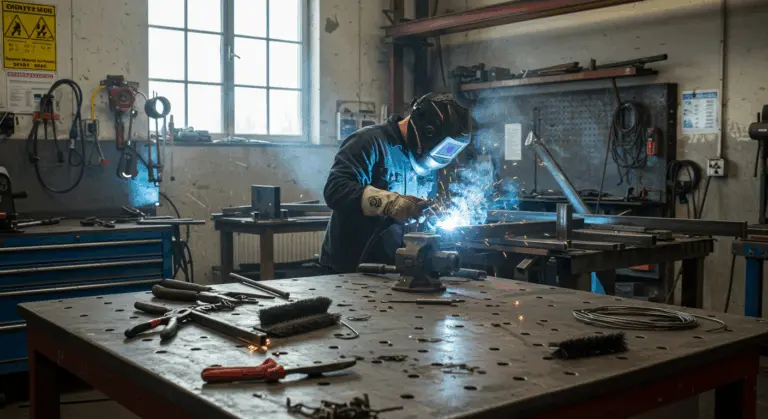

What Are TIG Welding Defects?

In metalworking, TIG welding defects represent flaws that compromise a weld’s integrity, strength, and overall functionality. These imperfections can emerge from improper technique, equipment malfunctions, or material-related issues. TIG weld quality is critical since this process is chosen specifically for precision and clean results.

Common TIG welding defects include:

-

Undercut

-

Porosity

-

Cracks

-

Burn-through

-

Incomplete fusion

-

Incomplete penetration

These defects fall under international standards like ISO 6520, with acceptable limits clearly defined in ISO 5817 and ISO 10042. Understanding how to identify these defects is essential—even minor flaws can seriously compromise a joint’s structural integrity, potentially triggering premature failure.

TIG welding defects can be broadly categorized into external defects (visible to the naked eye) and internal defects (requiring specialized testing to detect). External defects include visible oxidation, undercutting, and spatter. Internal defects include porosity or lack of fusion that isn’t immediately apparent. Consistent equipment maintenance, proper material preparation, and correct welding techniques are essential for minimizing these defects and ensure high-quality, durable welds.

Types of External Welding Defects

External welding defects manifest as surface-level flaws visible to the naked eye. These defects affect a weld’s appearance, but also compromise structural integrity, affecting the clean, precise results TIG welding is known for.

The most common external defects include:

-

Cracks

-

Porosity

-

Overlap

-

Burn-through

-

Spatter

-

Underbilled welds

-

Excess reinforcement

-

Mechanical damage

-

Distortion

-

Misalignment

Each defect has specific causes that welders must understand preventing them. Unlike internal defects, external flaws provide immediate visual feedback that the welding process needs adjustment.

Identifying external defects early is crucial for quality control because it saves both time and resources by preventing costly rework or component failure. Proper training, experience, and meticulous attention to detail enable welders to recognize these defects as they form and take immediate corrective action.

Cracks in TIG Welding

Cracks are among the most serious TIG welding defects. These fractures can spread under stress and lead to complete joint failure.

TIG welding cracks are classified by their location and formation:

-

Longitudinal cracks: Run parallel to the weld axis.

-

Transverse cracks: Form perpendicular to the weld axis.

-

Crater cracks: Appear in the final weld crater from improper arc termination.

-

Hot cracks: Form at high temperatures during weld metal solidification.

-

Cold cracks: Develop after the weld has cooled, often due to hydrogen embrittlement.

The primary causes of cracking include improper weld preparation, poor material selection, excessive restraint, high cooling rates, and contamination. Prevention requires several techniques: properly preheating the material, controlling interpass temperatures, selecting appropriate filler metals, ensuring materials remain clean, and employing correct welding sequences to manage stress. Addressing these factors significantly reduces cracking risk and ensures stronger, more reliable welds.

Porosity in Welds

Porosity refers to tiny gas cavities trapped within the weld metal as it solidifies. These appear in several forms: distributed porosity (small pores scattered throughout the weld), surface-breaking pores (visible on the weld surface), wormholes (elongated cavities), and crater pipes (shrinkage cavities at the weld’s end). While minor porosity may be acceptable, excessive amounts weaken the weld by reducing its effective cross-sectional area.

The main causes of porosity in TIG welds are contamination, moisture, and shielding gas issues. Contamination—oil, grease, paint, or rust on the base material or filler rod—releases gas when heated. Moisture from humidity or improper material storage introduces hydrogen into the weld pool. Inadequate shielding gas, whether from incorrect flow rates, drafts, or extended arc length, compromises the protective gas envelope.

Preventing porosity requires welders to thoroughly clean all materials before welding, store filler rods properly to avoid contamination, and use the correct gas flow rate (typically 15-20 CFM). Additionally, employ larger gas cups for better coverage, shield the welding area from drafts, maintain proper torch angle and arc length, and slightly preheat the workpiece to drive off moisture. These steps help produce dense, porosity-free welds with optimal mechanical properties.

Geometric Defects: Undercut and Overlap

| Defect | Description | Common Causes |

|—|—|—|

| Undercut | A groove at the weld toe where the base metal melted but was not filled. It creates a stress concentration point. | • Excessive travel speed

• Incorrect torch angle

• Excessive current |

| Overlap | Weld metal flows over the base material without fusing to it, creating a sharp notch that can initiate cracks. | • Insufficient heat input

• Improper torch angle

• Inadequate cleaning |

Both defects are especially problematic in fatigue-loaded applications. Prevention requires welders to:

-

Maintain a proper travel speed.

-

Use appropriate amperage for the material thickness.

-

Position the torch at the correct angle (typically 15–20 degrees from vertical).

-

Ensure all surfaces are thoroughly cleaned.

Types of Internal Welding Defects

Internal welding defects are flaws hidden within the weld that remain invisible on the surface but can severely compromise the joint’s structural integrity. Because they remain hidden, these flaws can trigger unexpected failures, making them a significant concern in high-quality TIG applications.

Common internal TIG welding defects include:

-

Porosity: Gas pockets trapped within the weld.

-

Slag Inclusions: Non-metallic material trapped in the weld metal.

-

Lack of Fusion: Incomplete melting between the weld and base metal.

-

Lack of Penetration: Insufficient weld metal at the root of the joint.

-

Internal Cracks: Fractures contained entirely within the weld or heat-affected zone.

These defects can result from improper welding parameters, poor joint preparation, contamination, or incorrect technique.

Unlike external defects that reveal themselves through visual inspection, internal defects demand specialized non-destructive testing methods for detection. Their hidden nature makes them more dangerous since they may go undetected until failure occurs. Understanding internal defect causes and characteristics is essential for implementing effective prevention strategies and ensuring weld quality in critical applications.

Slag Inclusion and Its Causes

Slag inclusion refers to non-metallic solid material that becomes trapped within the weld metal during welding. While slag inclusions are more commonly associated with flux-based processes like stick welding (SAW) or flux-cored arc welding (FLAW), they can still occur in TIG welding—particularly when welding materials with high oxide content or using certain filler metals.

In TIG welding, slag inclusions typically form from several factors: incorrect welding angle (preventing the arc from properly cleaning the weld pool), poor pre-cleaning (leaving contaminants that form slag), low current density (providing insufficient heat to float contaminants to the surface), and improper interpass cleaning (trapping slag between layers in multi-pass welds).

To prevent slag inclusions in TIG welds, welders should thoroughly clean base materials and filler rods to remove oxides and contaminants, maintain a proper travel angle (15–20 degrees from vertical) for effective arc cleaning action, use sufficient amperage to melt contaminants and allow them to float out, and clean thoroughly between passes on multi-pass welds.

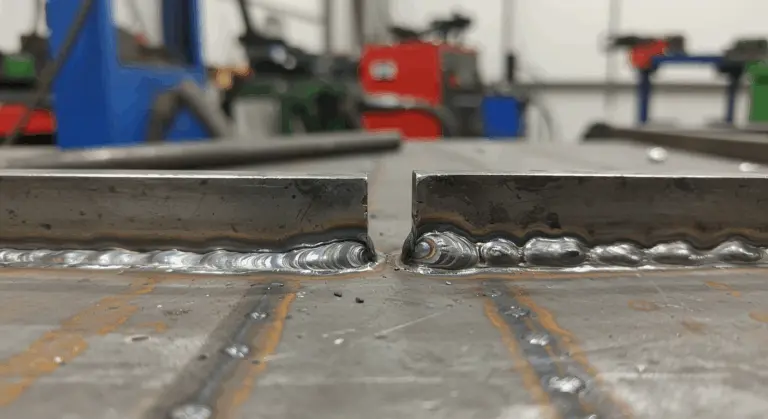

Incomplete Fusion and Penetration

Incomplete fusion and incomplete penetration represent serious internal defects that significantly compromise weld strength and integrity. Incomplete fusion occurs when the weld metal fails to properly melt and coalesce with either the base material or previous weld passes. This creates a cold lap where metals are stacked against each other rather than truly fused, resulting in a weak point that can easily fail under load.

Incomplete penetration specifically refers to insufficient weld metal reaching and fusing at the joint’s root. In butt welds, this creates an unfused region at the bottom where the two pieces meet. This defect is especially problematic because it creates a natural crack-like discontinuity at a high-stress location, often leading to premature failure.

Several factors contribute to these defects: insufficient heat input (caused by low amperage or excessive travel speed), improper joint preparation (insufficient root gap or incorrect joint angle can block the weld), and poor technique (incorrect torch angle or filler rod manipulation). To prevent incomplete fusion and penetration, welders should use appropriate root gaps and matching filler wire diameters, ensure adequate heat input by adjusting amperage and travel speed, employ proper weaving techniques, maintain correct torch angles, and for thicker materials, use proper joint beveling to allow full root access.

Detection Methods for Welding Defects

Detecting welding defects is crucial for ensuring the structural integrity and performance of welded components. Methods for identifying external and internal defects in TIG welds range from simple visual inspection to advanced technological approaches. These detection methods fall into two broad categories: non-destructive testing (NDT), which preserves the welded component, and destructive testing, which involves deliberately breaking or damaging the weld to evaluate its properties.

Thorough inspection is critical for TIG welds, especially in high-stakes applications. Visual inspection serves as the first line of defense for identifying external defects like cracks or undercut. However, detecting internal defects requires more advanced non-destructive testing (NDT) methods detailed below.

The choice of detection method depends on several factors: the critical nature of the application, weld accessibility, material type, and specific defects of concern. In critical industries like aerospace, nuclear, or pressure vessel manufacturing, multiple inspection methods are often used together for comprehensive defect detection. Establishing proper inspection protocols and acceptance criteria based on relevant codes and standards is essential for effective quality control in TIG welding applications.

Non-Destructive Testing Techniques

Non-destructive testing (NDT) enables TIG weld inspection without damaging components. Common NDT techniques include Visual Testing (VT)—the most basic method using direct vision or tools to find surface defects—and Liquid Penetrant Testing (PT), where dye seeps into surface-breaking flaws, making them highly visible. Magnetic Particle Testing (MT) uses magnetic fields to reveal surface and near-surface defects in ferromagnetic materials. Ultrasonic Testing (UT) employs high-frequency sound waves to detect internal discontinuities and provide information on their size, shape, and location. Radiographic Testing (RT) uses X-rays or gamma rays to create interior weld images, revealing voids, inclusions, or cracks. Eddy Current Testing (ET) uses electromagnetic induction to find near-surface flaws, especially in thin materials. These methods are often combined to ensure comprehensive inspection coverage for critical TIG welded components.

Destructive Testing Methods

Destructive testing involves breaking welded samples to evaluate their mechanical properties and internal quality. These tests validate welding procedures and qualify welders. Common methods include the Tensile Test (pulling a specimen until failure to measure ultimate tensile strength, yield strength, and ductility), Bend Test (bending a specimen to a specified angle to reveal defects like lack of fusion or inclusions on the outer surface), Nick Break Test (breaking a notched specimen open to examine internal weld structure for defects), and Macro Etch Test (polishing and etching a weld cross-section to reveal microstructure, penetration profile, and internal flaws). By systematically applying these tests, manufacturers gain confidence in their welding procedures.

Preventing TIG Welding Defects

Preventing TIG welding defects requires a systematic approach addressing all aspects of the welding process—from material preparation to final inspection. TIG welding is especially sensitive to proper technique and environmental conditions. By implementing comprehensive preventive measures, welders can consistently produce high-quality, defect-free welds that meet or exceed industry standards.

A systematic approach is essential for preventing TIG welding defects. Key focus areas include Material Preparation (thoroughly cleaning all base materials and filler rods to remove contaminants like oil, grease, or rust—for materials like aluminum, removing the surface oxide layer becomes critical), Equipment Checks (ensuring the welding machine is calibrated, the tungsten electrode is correctly sized and prepared, and gas lines and torch components are in good condition), Welding Parameters (using correct amperage for material thickness, proper gas flow rates like 15-20 CFM, and high-purity shielding gas, typically argon), Welding Technique (maintaining consistent torch angle at 15–20 degrees from vertical, proper arc length, and correct filler rod manipulation), Environmental Control (shielding the welding area from drafts that can disrupt gas coverage and controlling for high humidity), and Systematic Inspection (implementing regular inspection procedures to detect and correct flaws early). Combining these measures with proper training ensures consistently high-quality welds.